Plastics Engineering

Plastics Engineering – Precision and Versatility in Mass Production

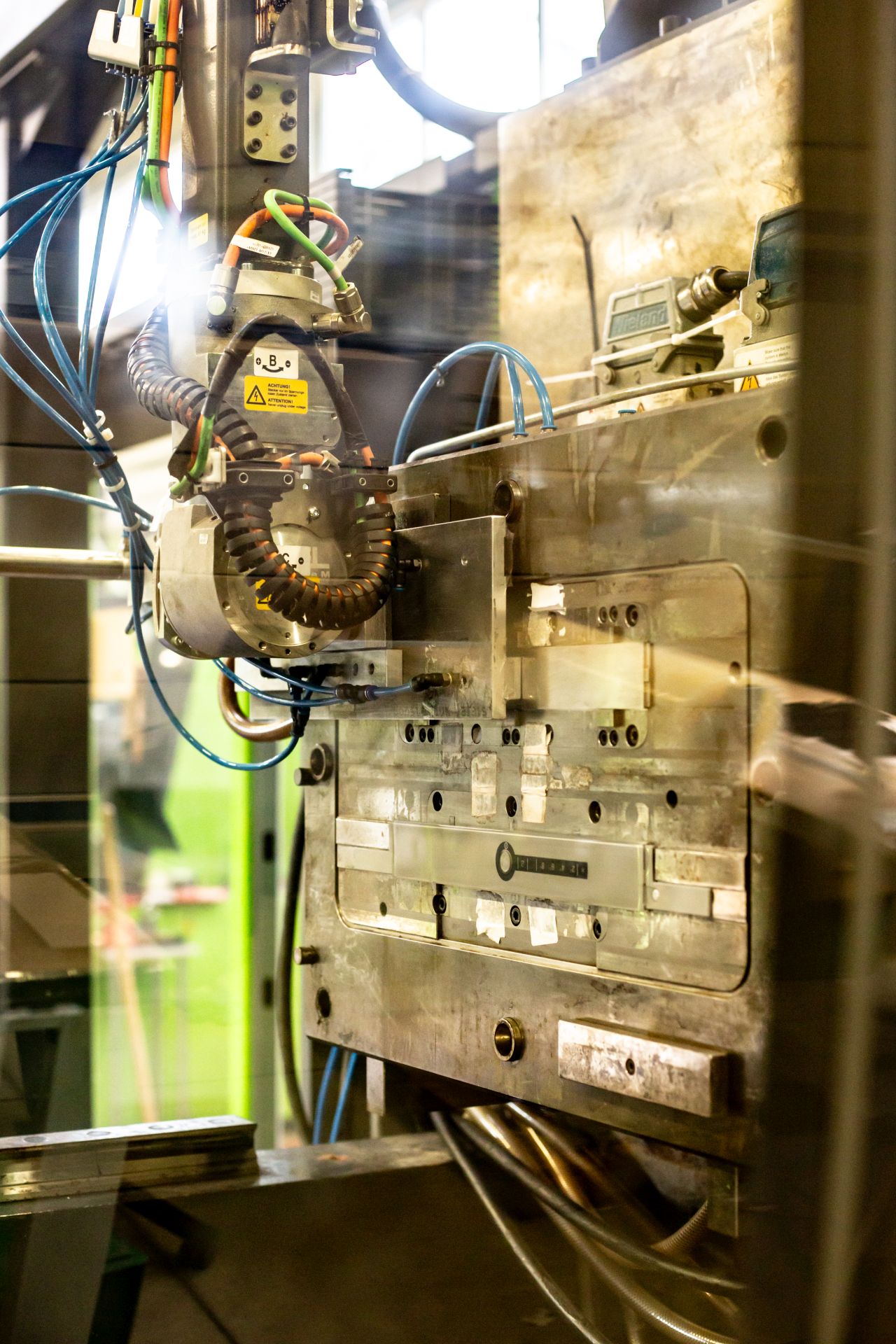

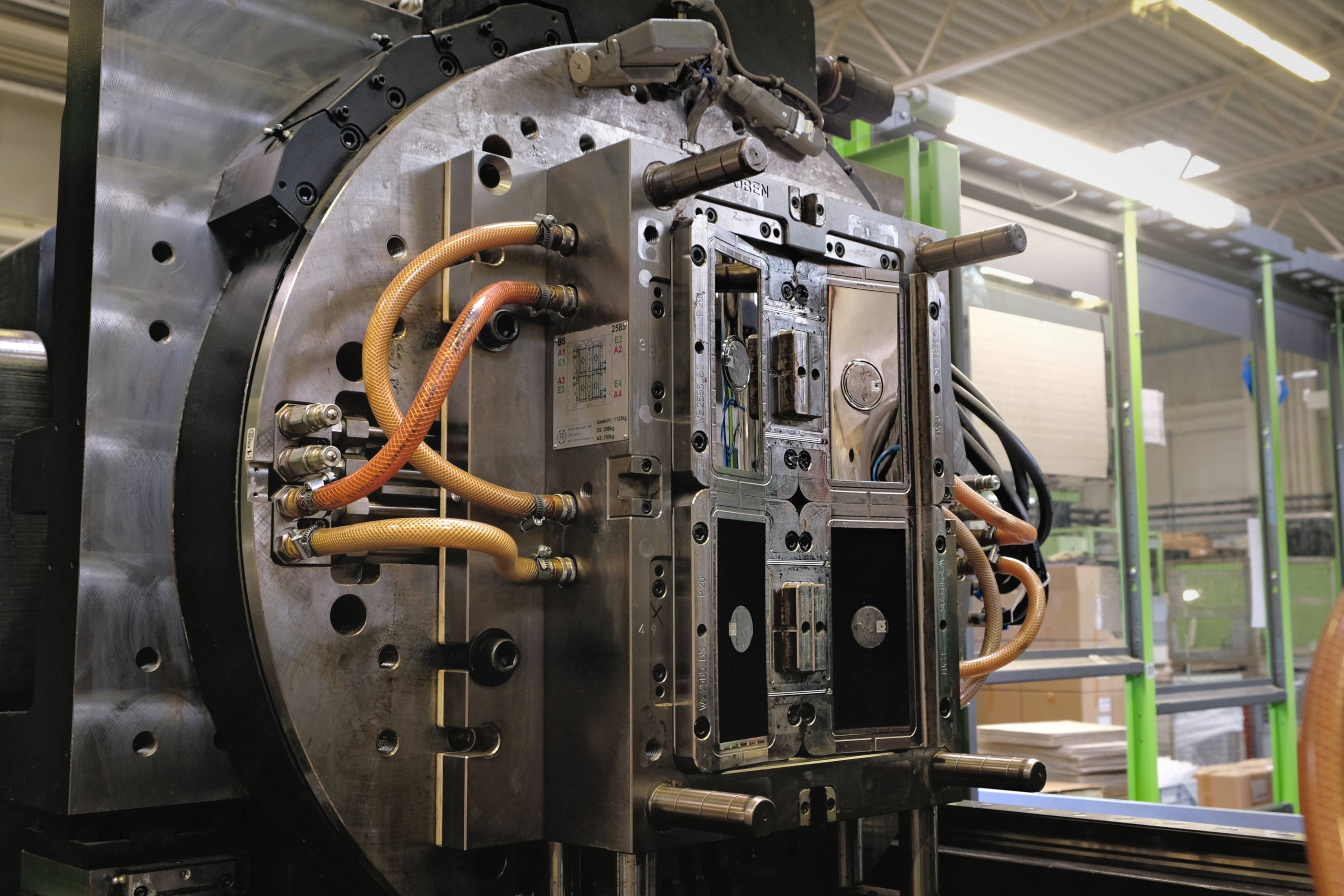

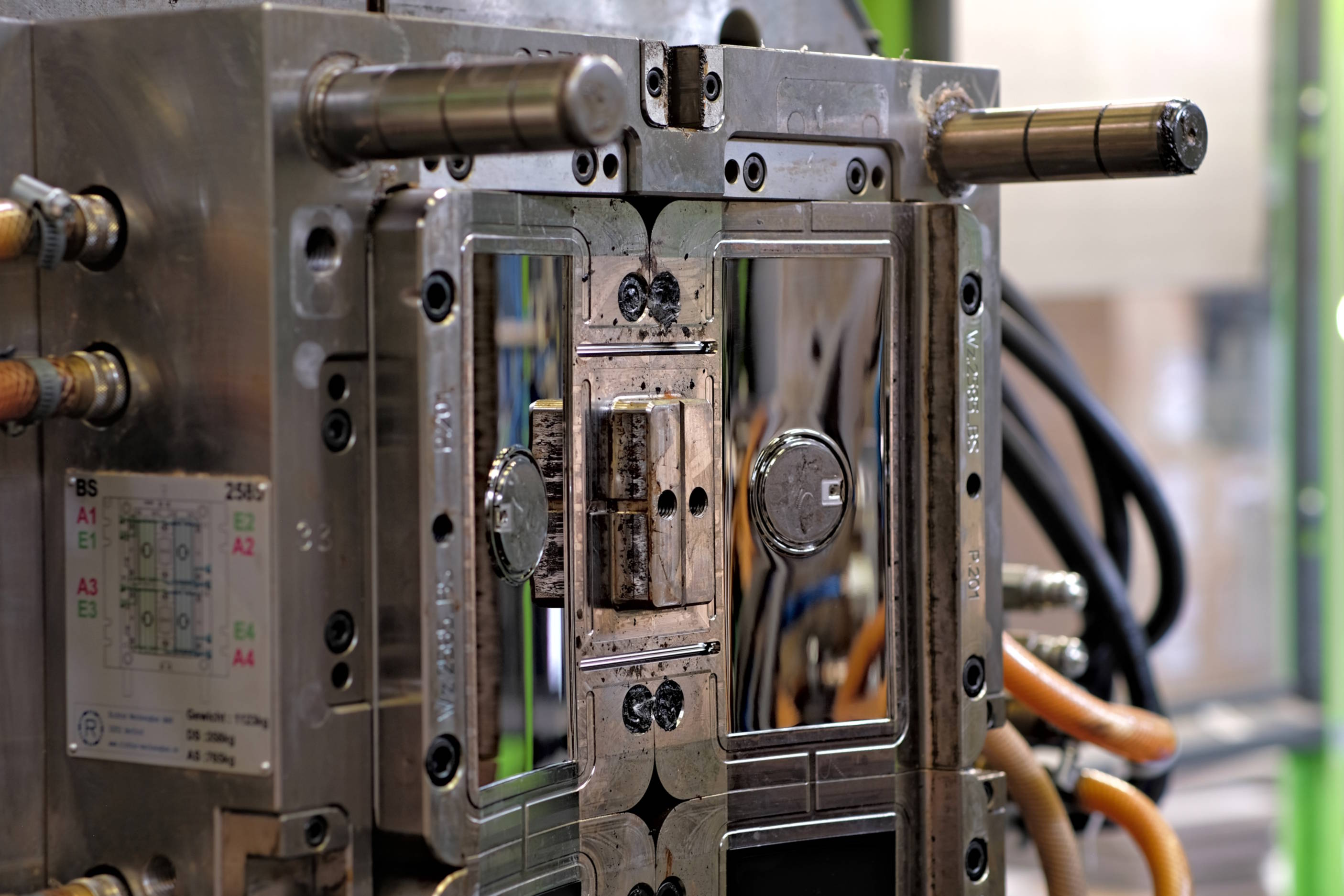

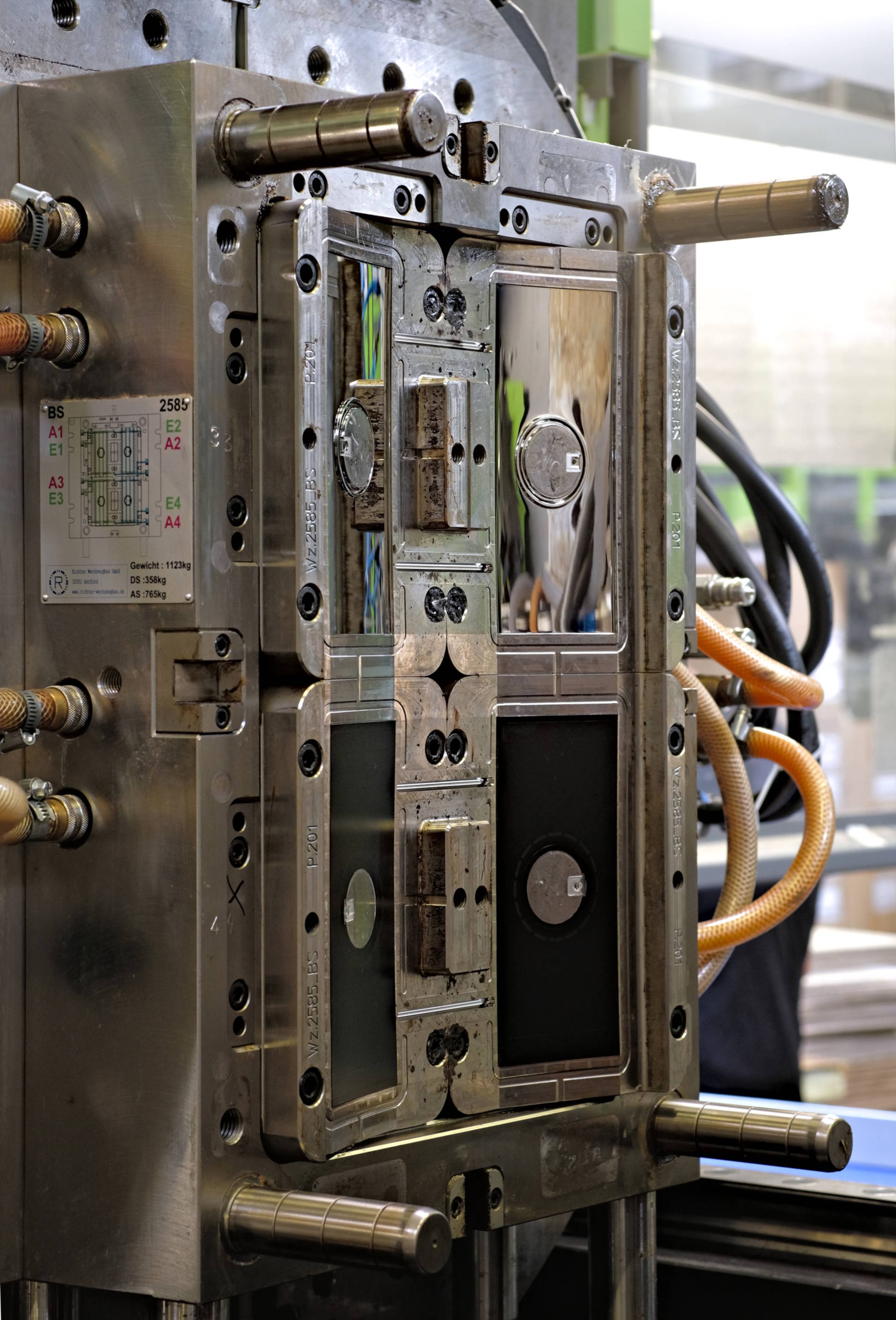

At Richter Werkzeugbau GmbH, our plastics engineering division combines state-of-the-art manufacturing technology with decades of expertise to deliver customized solutions for industrial applications. With our in-house developed and manufactured molds, we are capable of injection molding highly complex plastic parts with exceptional precision.

Sampling and Quality Control

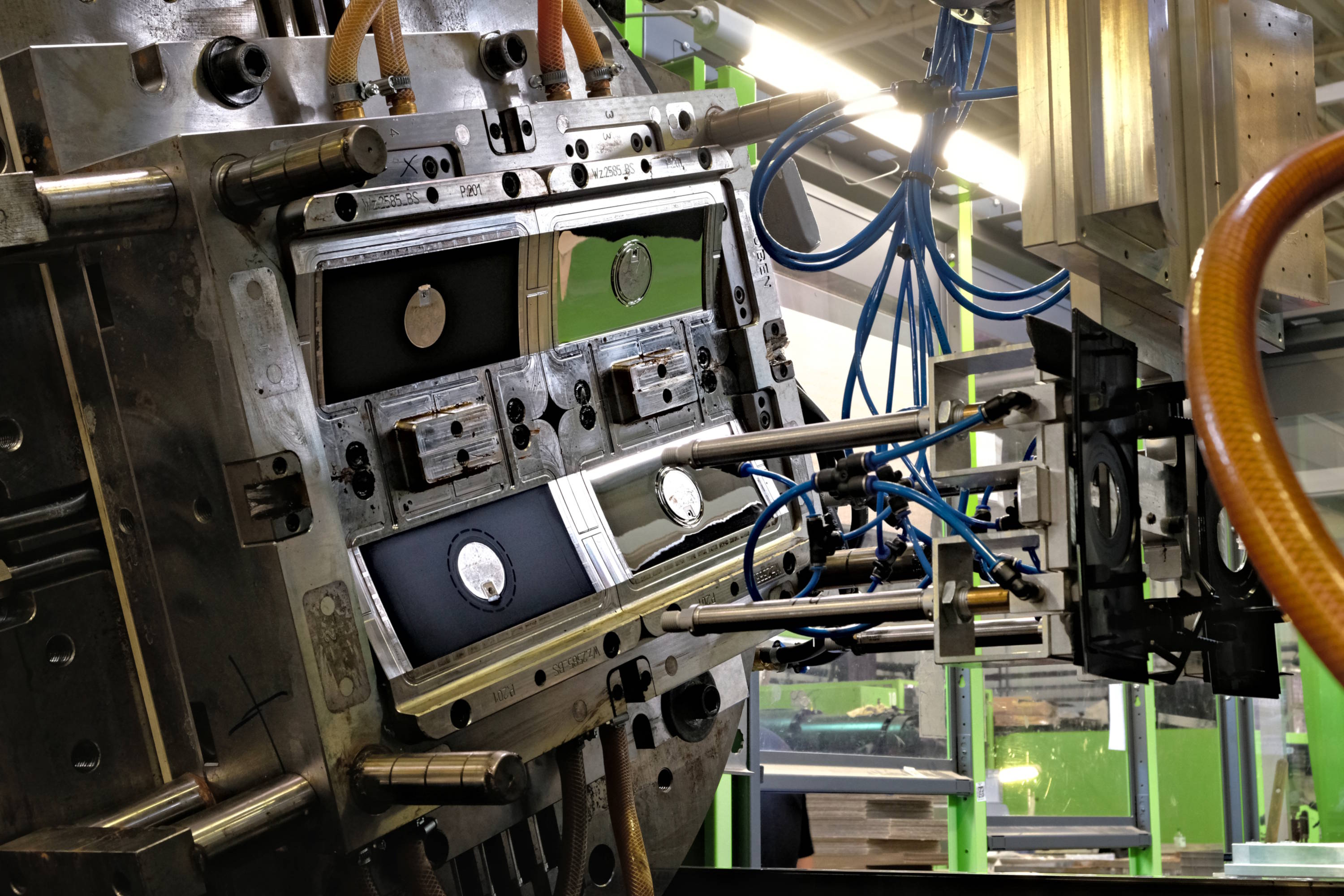

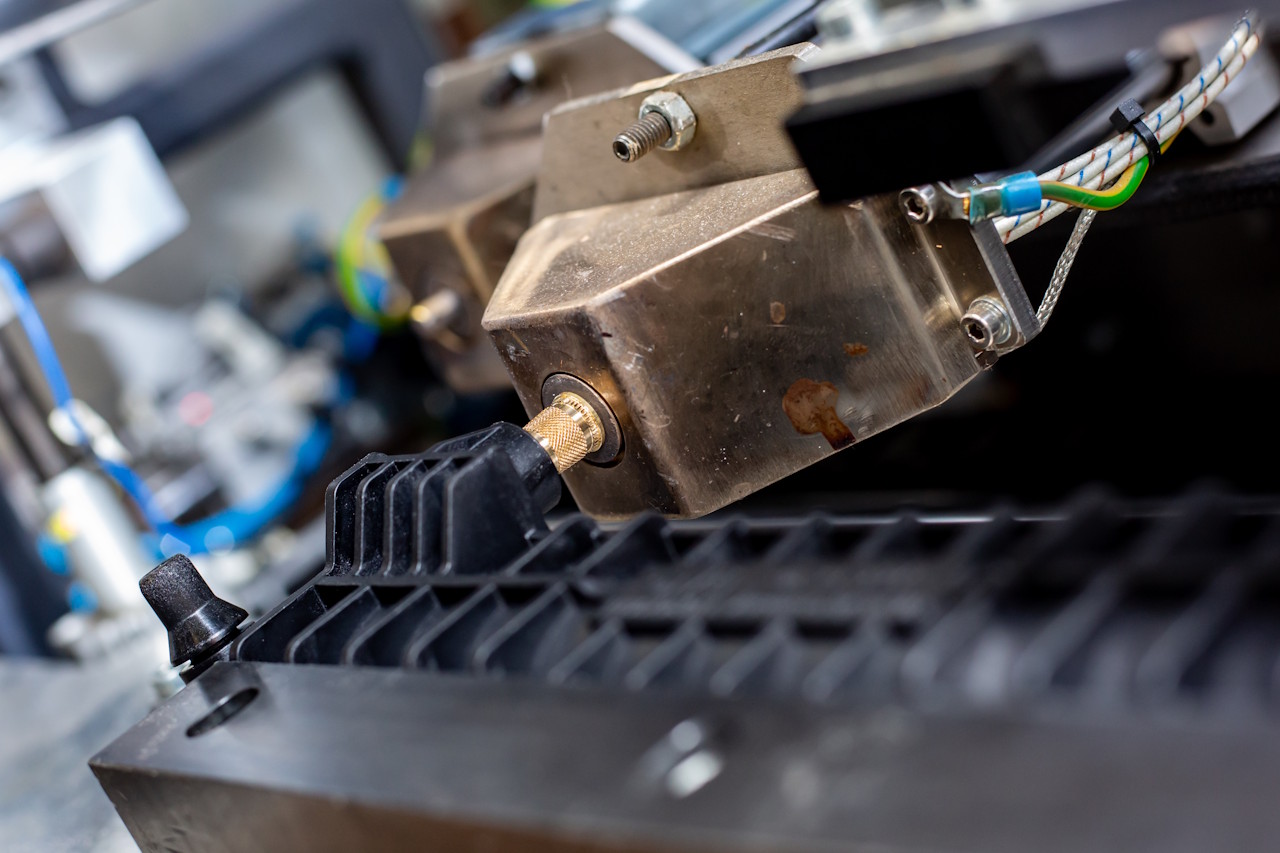

Each production run begins with detailed part sampling to ensure all required specifications are met. Comprehensive MoldFlow simulations allow us to optimize both the mold design and the production process in advance. Additionally, we rely on flow-optimized manufacturing and internal cavity pressure monitoring using sensor technology embedded in the mold. These methods enable precise process control and contribute significantly to ensuring consistently high product quality.

Post-Processing and Finishing

After injection molding, the plastic parts undergo thorough post-processing, accompanied by internal quality checks. All components are inspected for dimensional accuracy and functionality to meet our stringent quality standards.

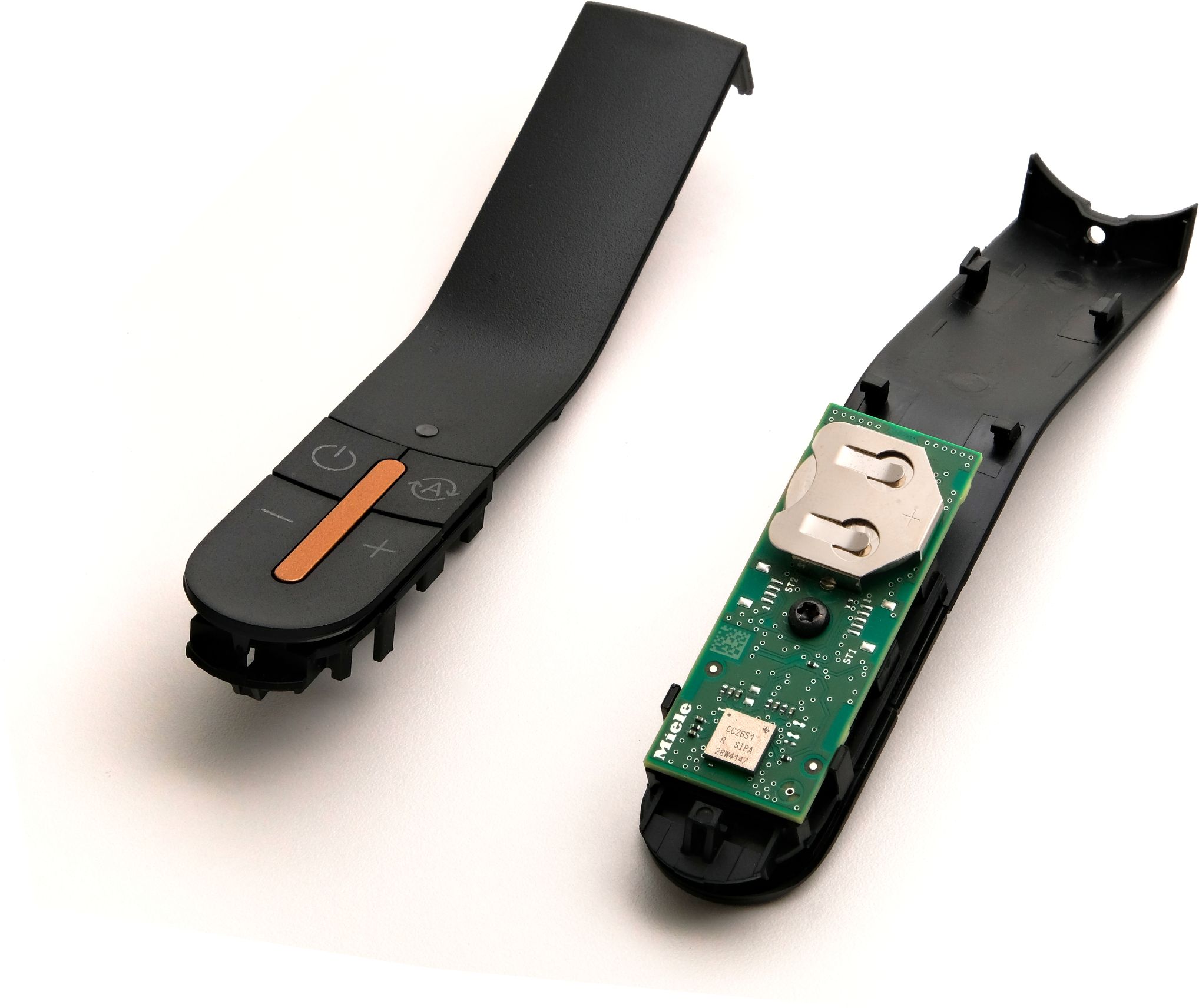

For functional and visual enhancement, we offer various finishing processes – including pad printing, hot stamping, and laser marking. Other options include plasma treatment to improve adhesive and paint bonding, as well as insertion of brass bushings into the molded plastic parts.

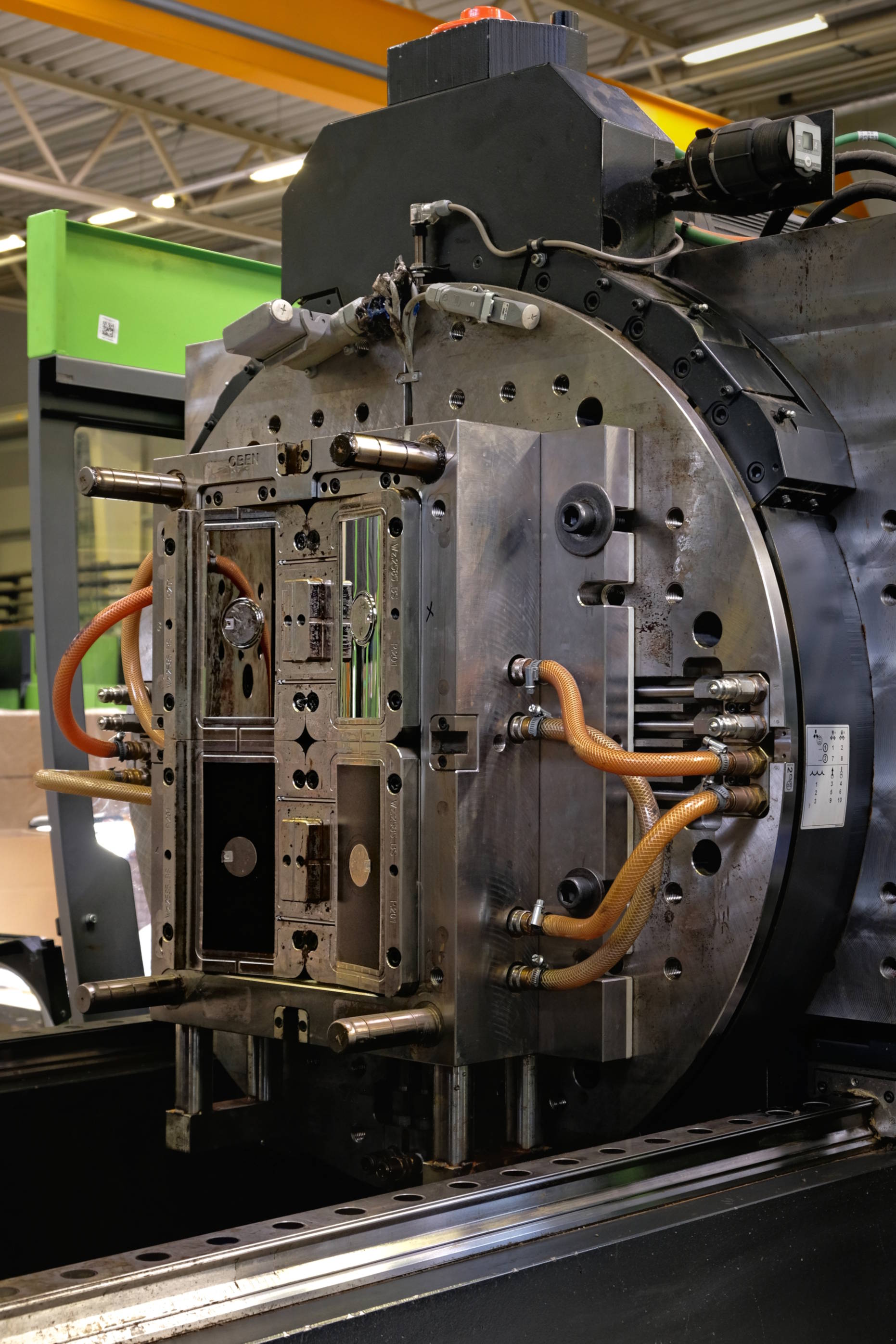

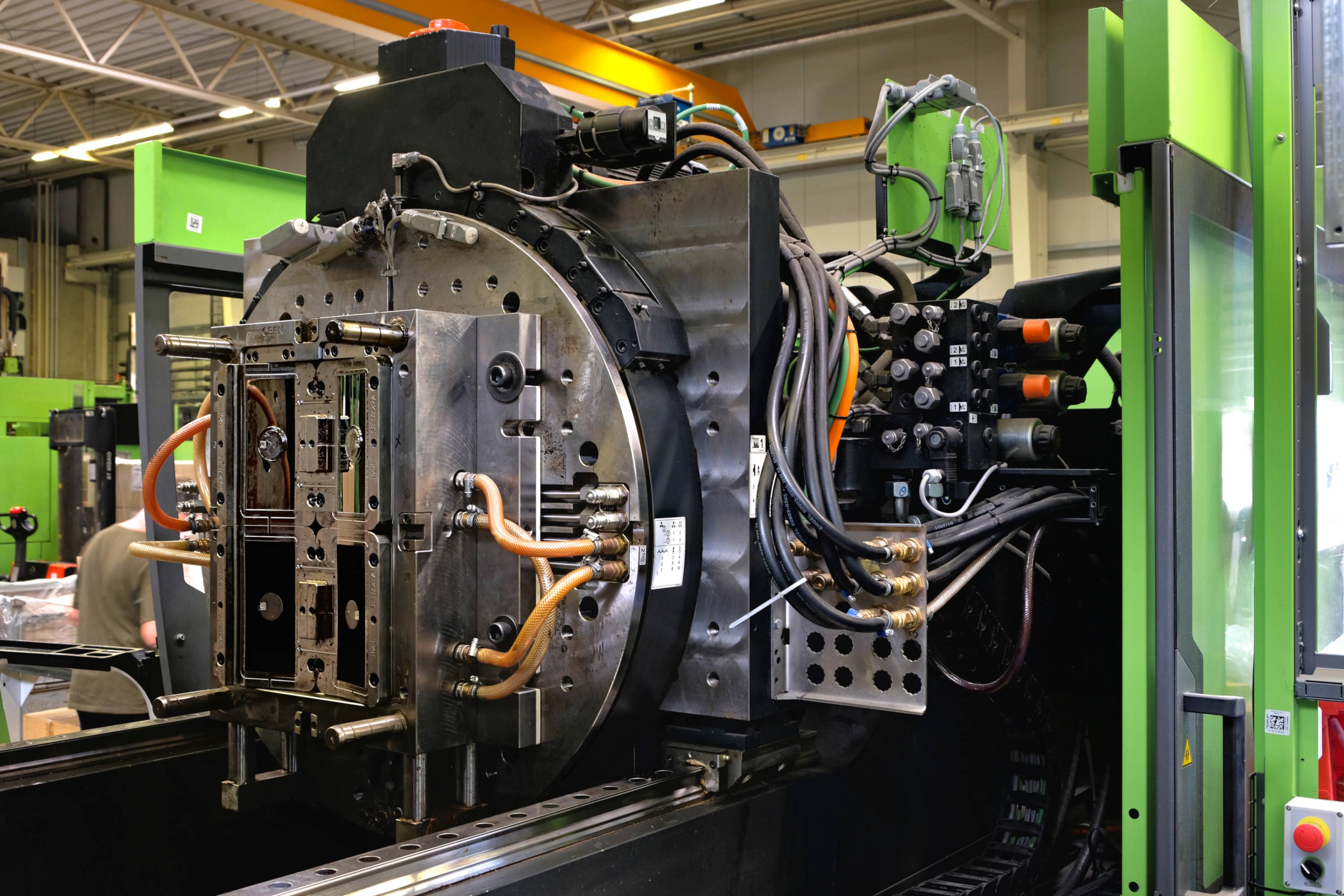

State-of-the-Art Machinery and Technology

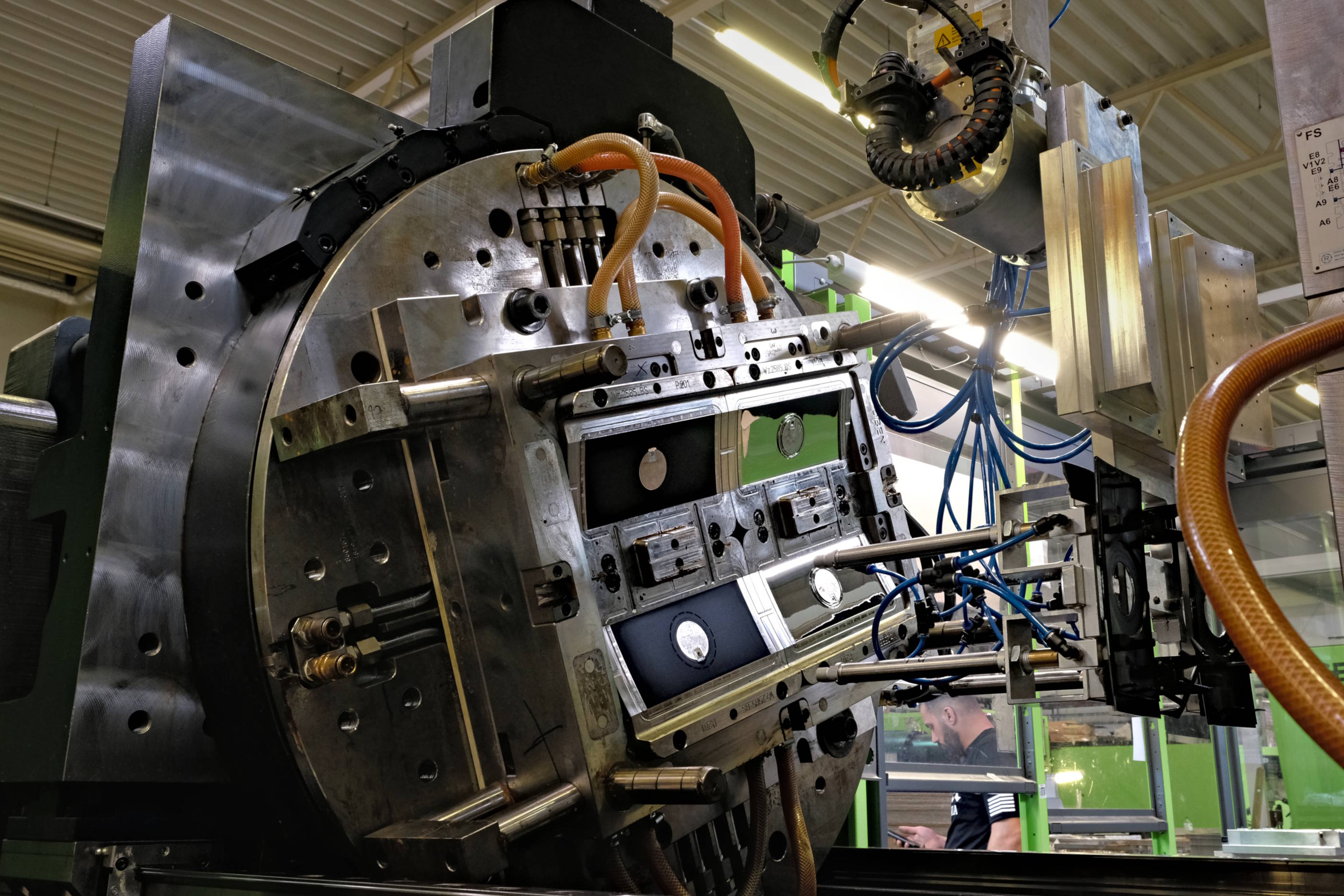

Our production relies on a modern machine park that enables economical and flexible manufacturing of diverse plastic parts. A total of 18 machines are available, offering clamping forces of up to 6000 kN and shot weights of up to 1000 grams. For sensitive applications, we provide a cleanroom environment that guarantees maximum cleanliness throughout the production process.

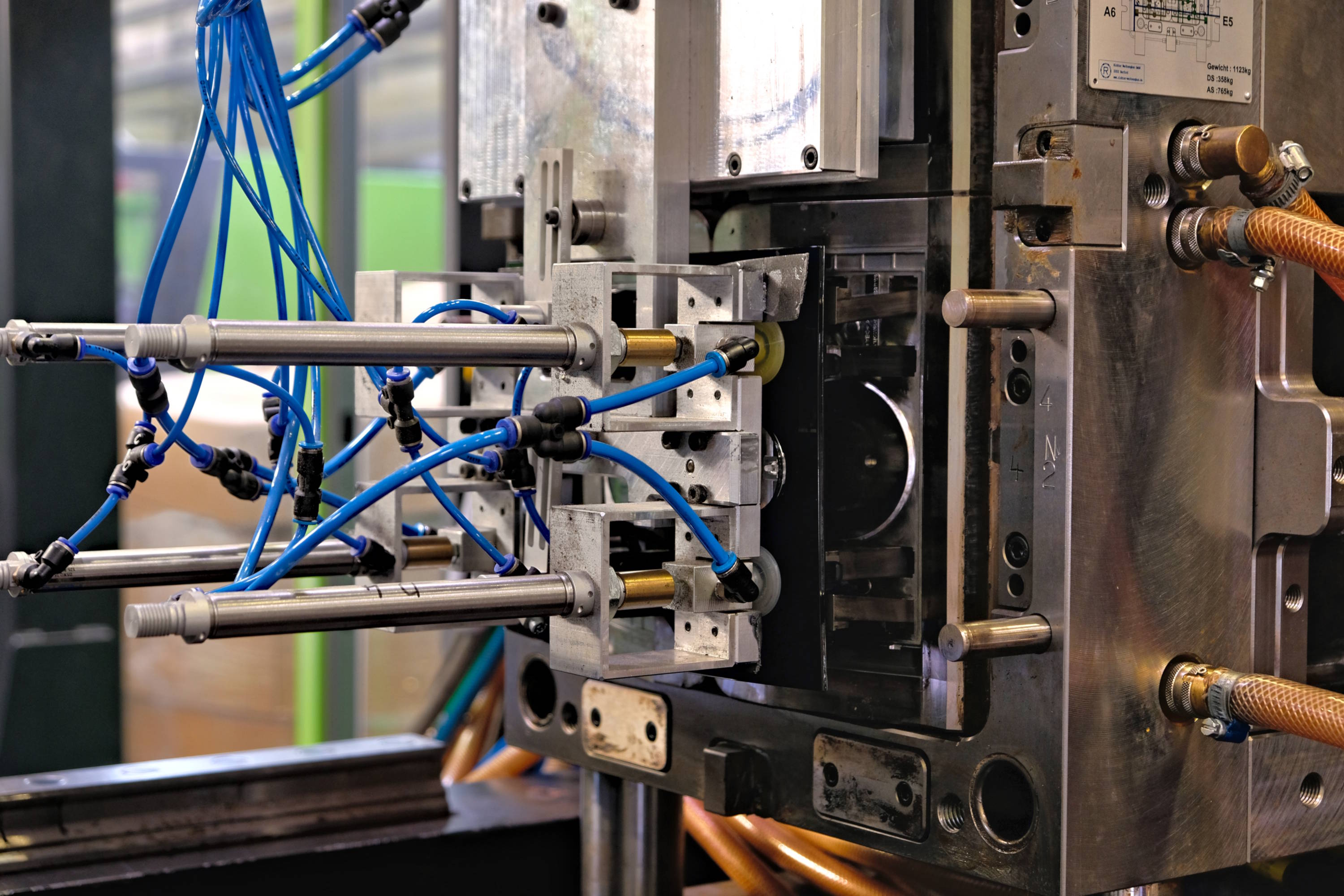

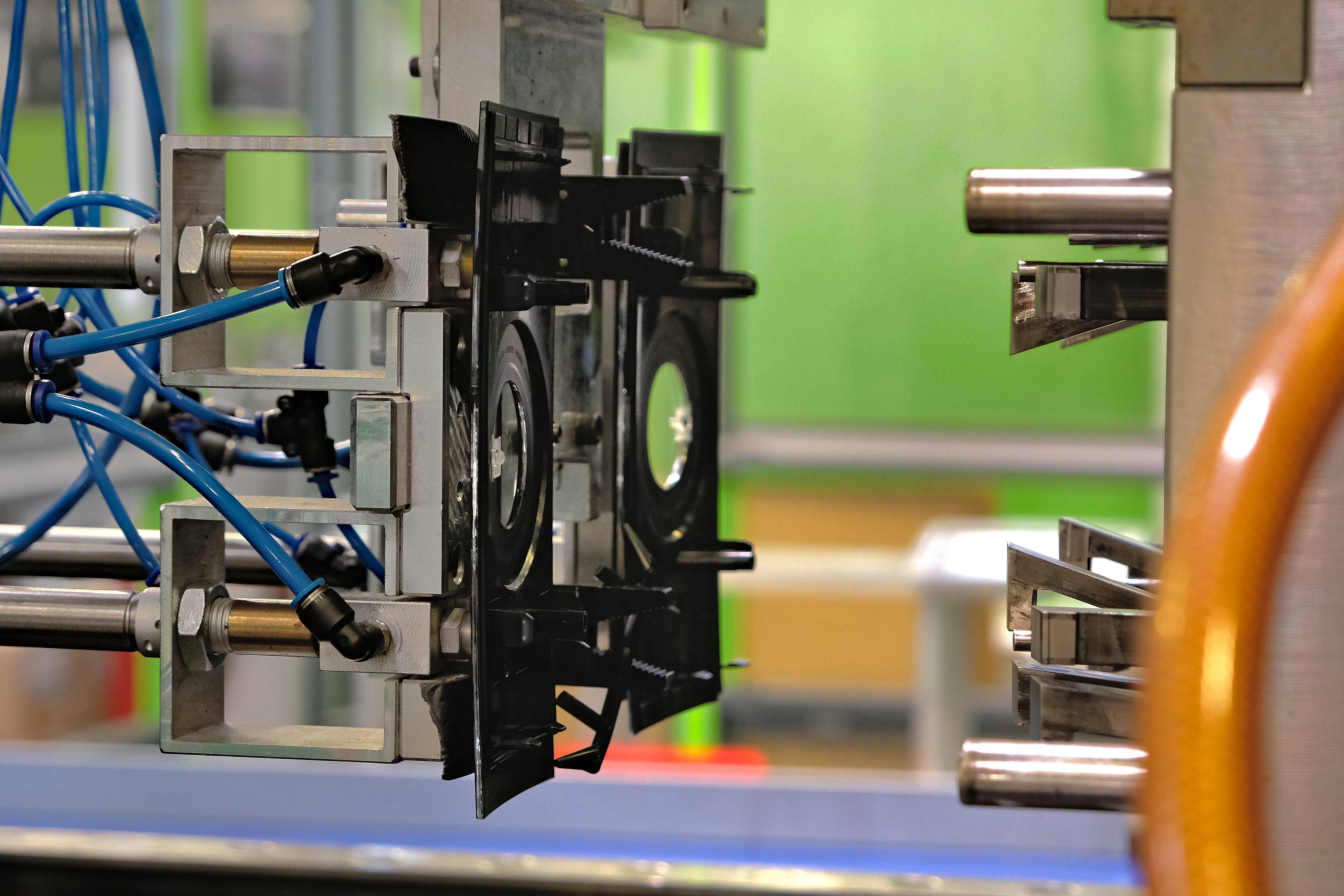

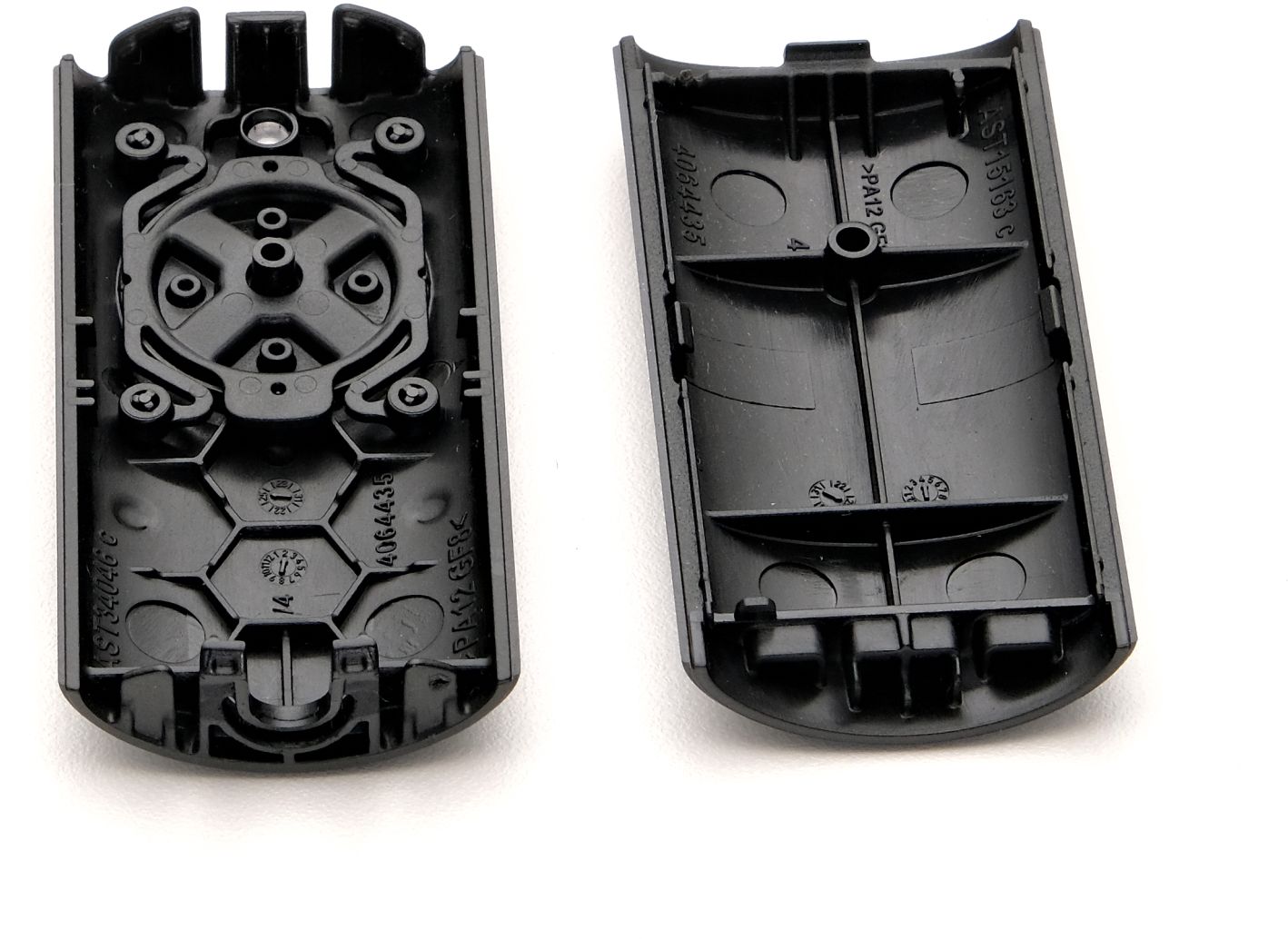

We use molds weighing up to 5 tons and apply advanced technologies such as rotary table systems and handling-based transfer techniques for multi-component or hybrid parts. Variothermal temperature control is used to avoid visible weld lines or flow marks, thereby improving surface quality.

For clear part identification, date stamps are applied during the molding process.

We also handle downstream assembly operations – such as hot staking as an alternative to gluing, screwing, riveting, or nailing small components – ensuring reliable and cost-efficient further processing.

Focus on Multi-Component Parts

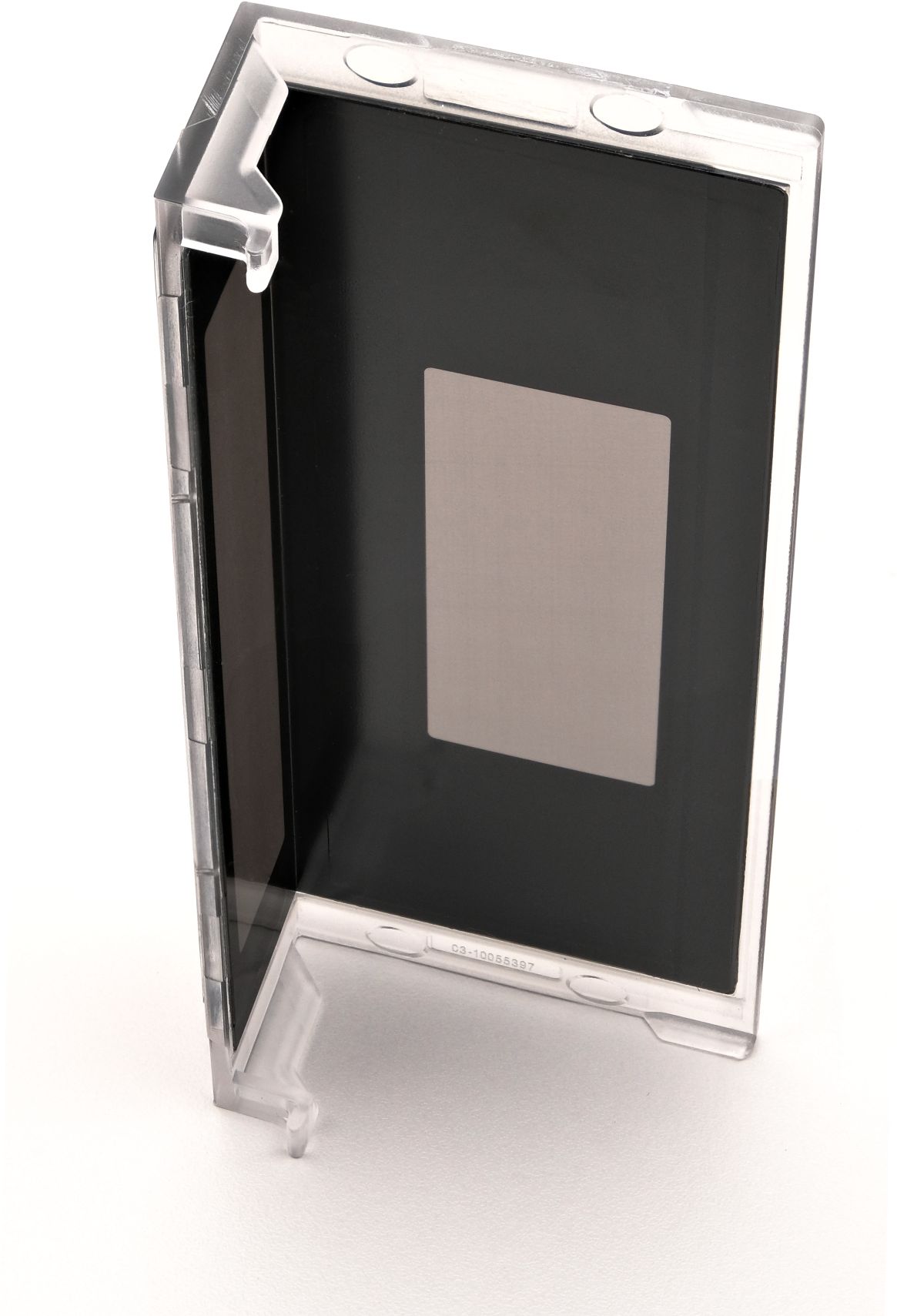

A key strength of our production lies in the manufacturing of two- and multi-component parts, including:

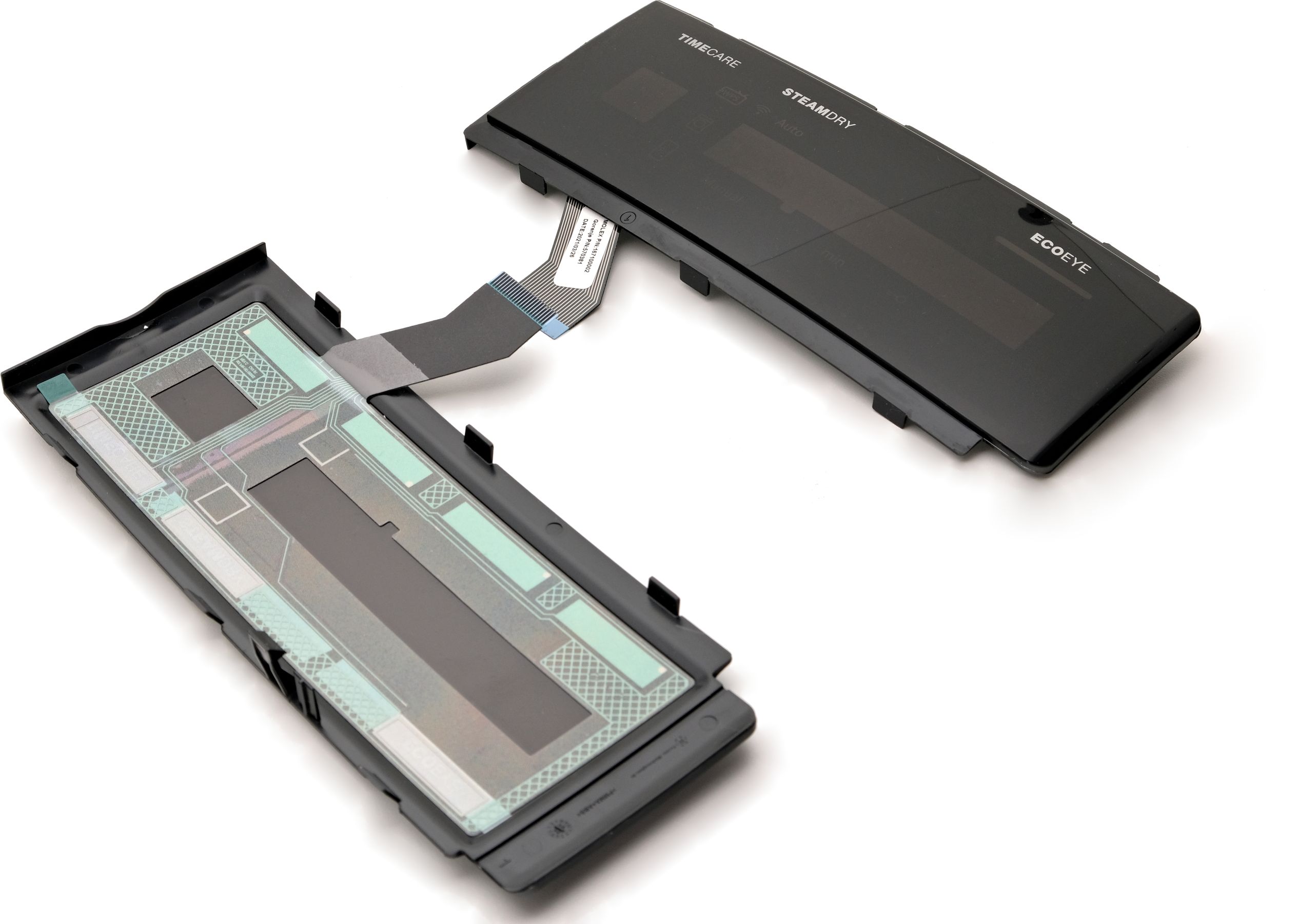

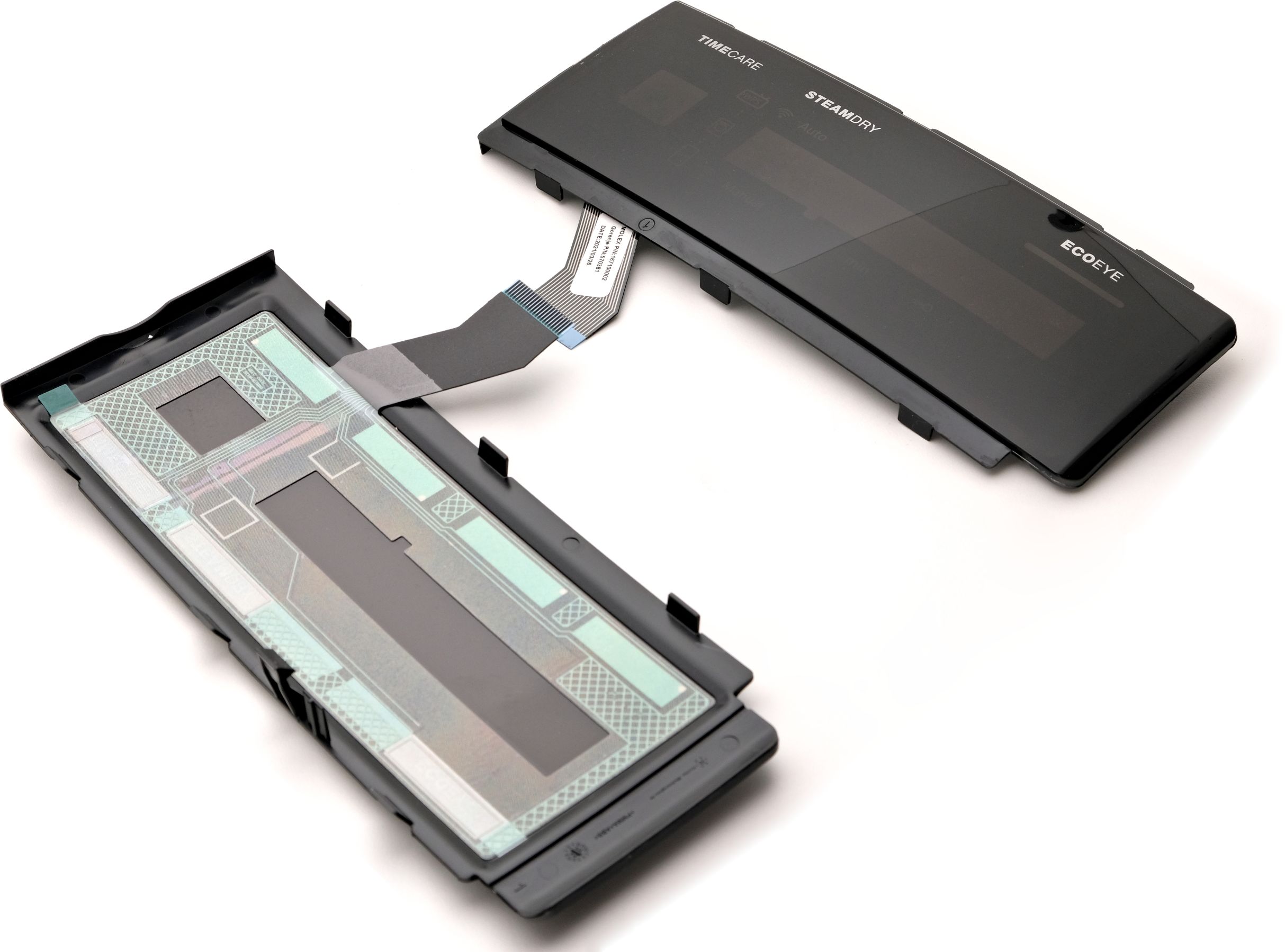

- Film back-injected components

- Overmolded bearings

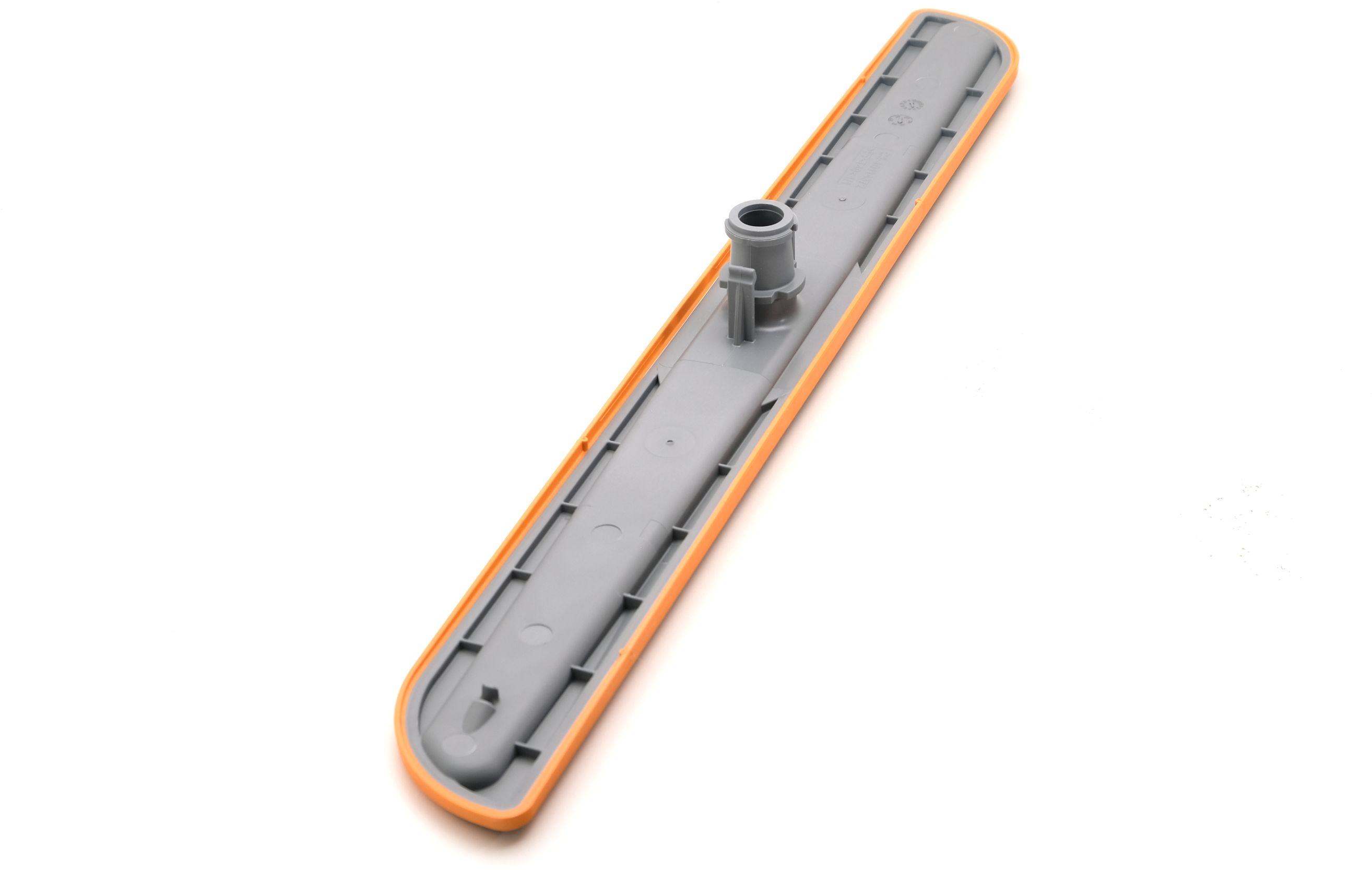

- Integrated sealing elements

- Transparent lenses

- Overmolding of metal and other inserts

Thanks to our extensive experience and technical capabilities, we are able to produce even the most demanding geometries and complex material combinations – precisely, repeatably, and in series.