Design

From Idea to Thought-Out Solution

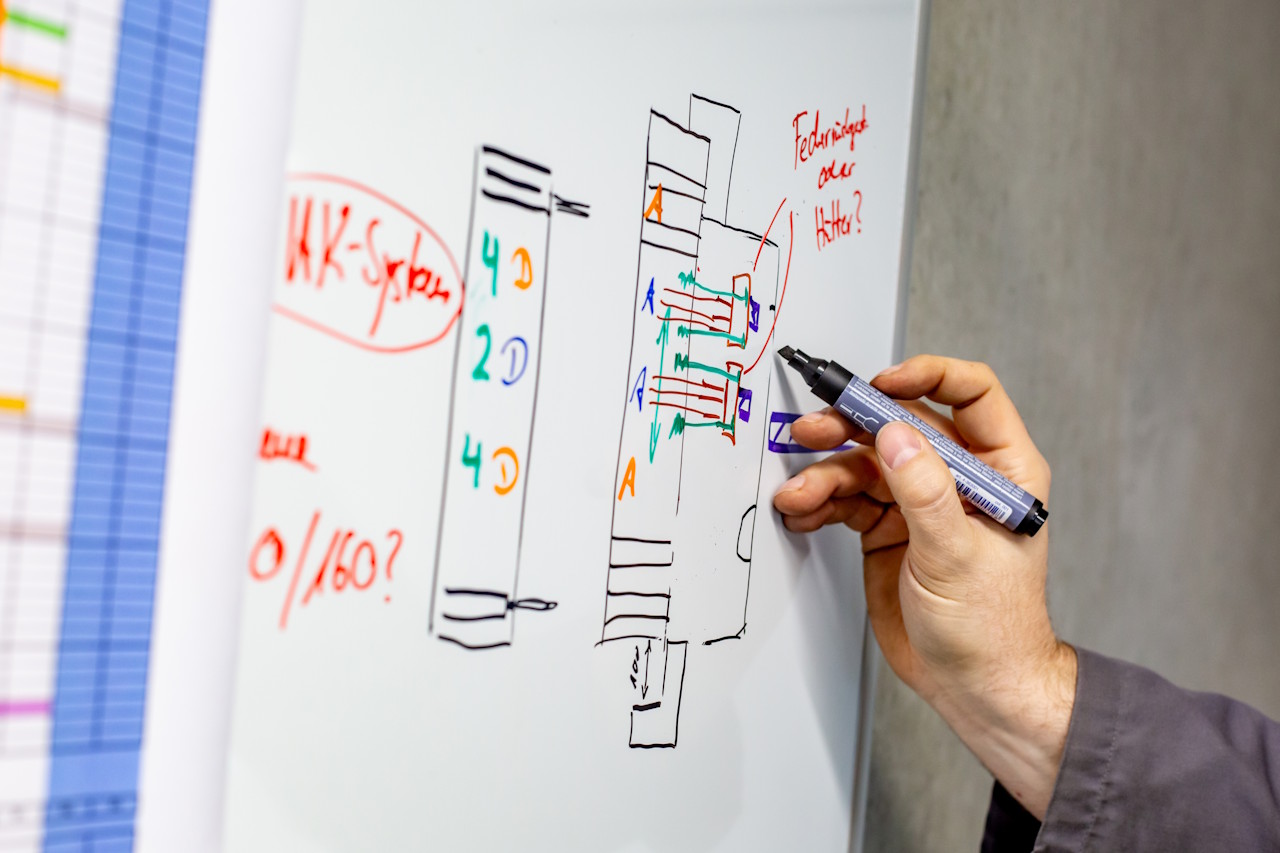

In the design department of Richter Werkzeugbau GmbH, every tool is created from scratch – from the initial sketch to a fully developed, ready-to-manufacture design. A proven mix of experience, expertise, and technical innovation is used throughout the process.

Our interdisciplinary team of trained specialists, master craftsmen, and engineers has been working closely together for many years. The combination of diverse qualifications results in well-thought-out solutions tailored to the customer – both functionally and economically.

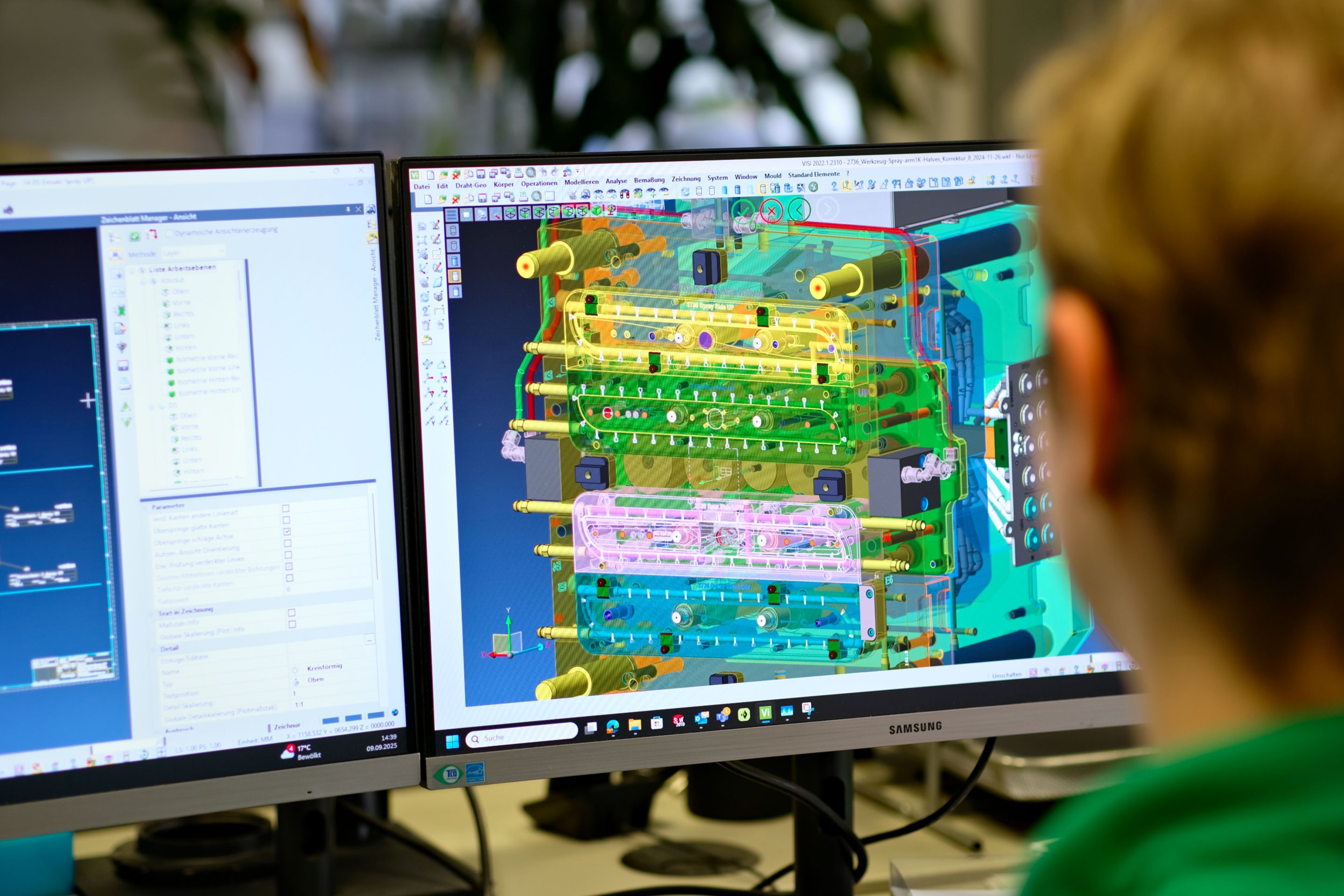

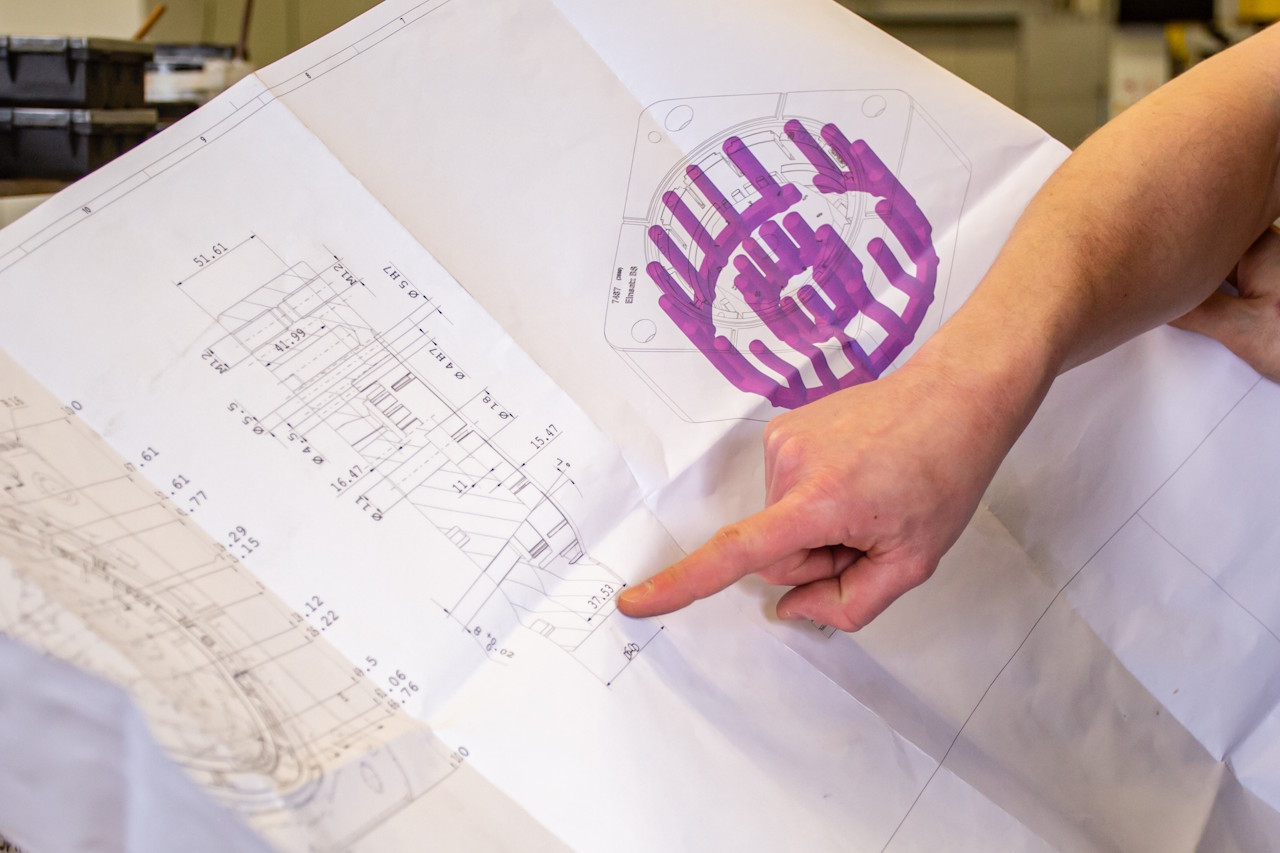

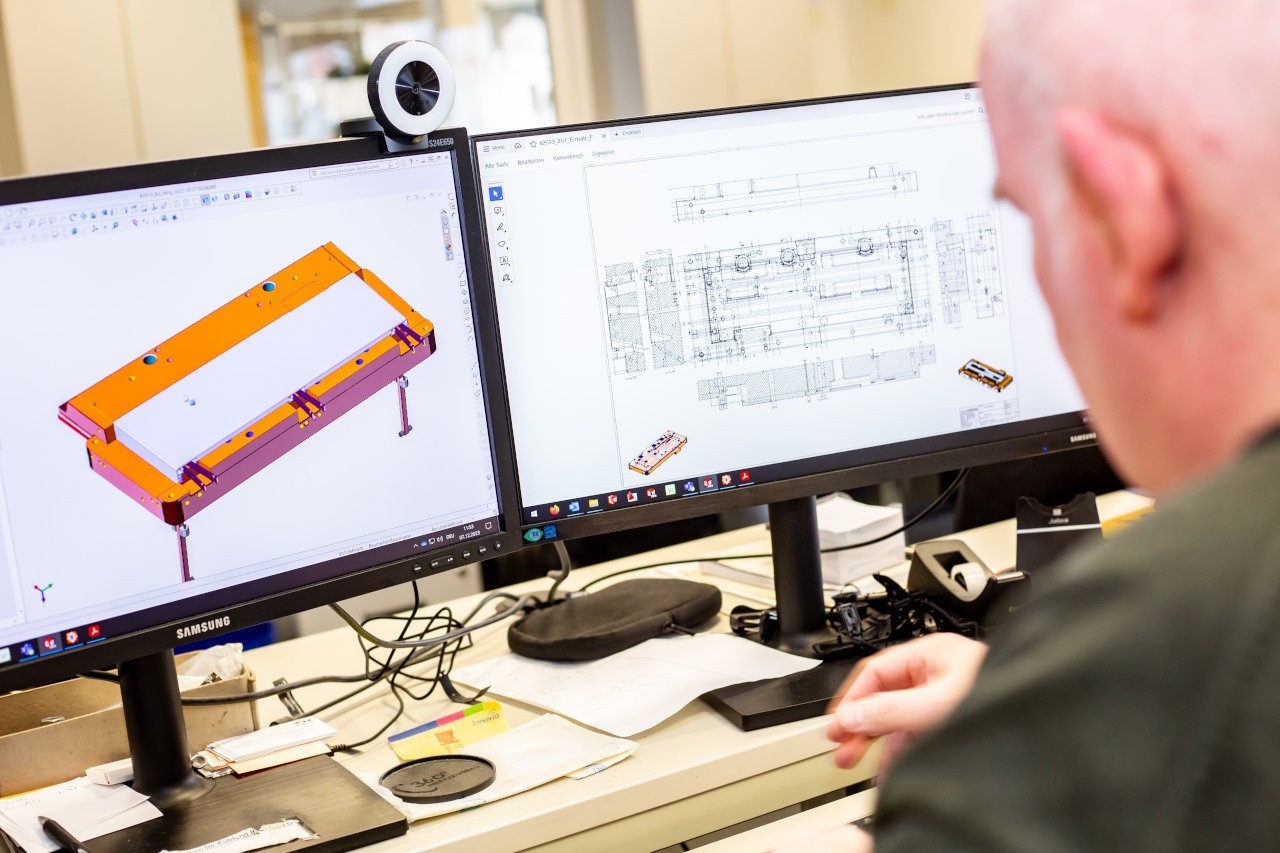

Using CAD systems such as SolidWorks and VISICAD, we successfully implement even the most demanding projects. When it comes to complex geometries in injection-molded parts, we develop creative, innovative, yet cost-conscious approaches to precisely realize individual customer requirements.

We are happy to support our customers early on during the product design phase. This can include complete part design based on purely visual concepts, which we make suitable for plastic manufacturing and functional performance.

We also assist in refining complex areas in terms of demoldability, functionality, and aesthetic requirements – always in close cooperation with our clients.

In coordination with our customers, we conduct MoldFlow analyses to simulate part filling and warpage in advance, helping to identify optimization potential that also affects the quality of the final part. A MoldFlow analysis supported by advanced tool temperature control further enhances development work by identifying thermally critical areas.

Our focus lies in the design of high-quality injection molds – from standard molds to slide tools (including collapsing core systems), stripper plate tools, stack molds, unscrewing tools with gear technology, tools with internal gating, as well as multi-component molds, some featuring index plates or core-back technology, and molds with insert parts (such as films, metal inserts, and similar components).

Depending on the application, we use a range of temperature control technologies beyond conventional systems to ensure optimal mold temperature: contour-close temperature control via SLM or HTP, variothermal temperature control, ceramic heating elements, and Hotset systems, among others, for optimizing weld line quality.

Sensor technologies such as pressure and temperature sensors are used to monitor and control the injection molding process.