Toolmaking

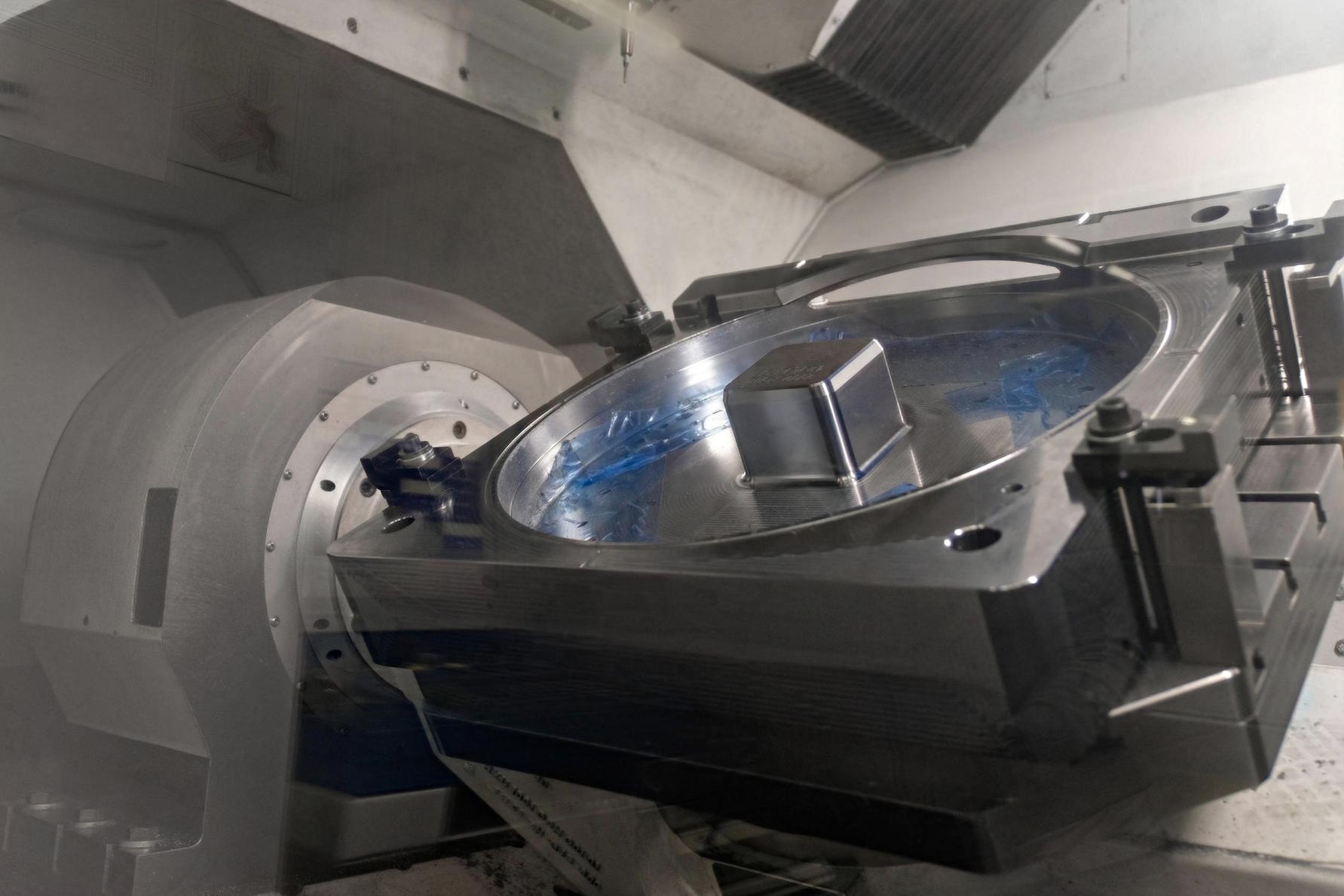

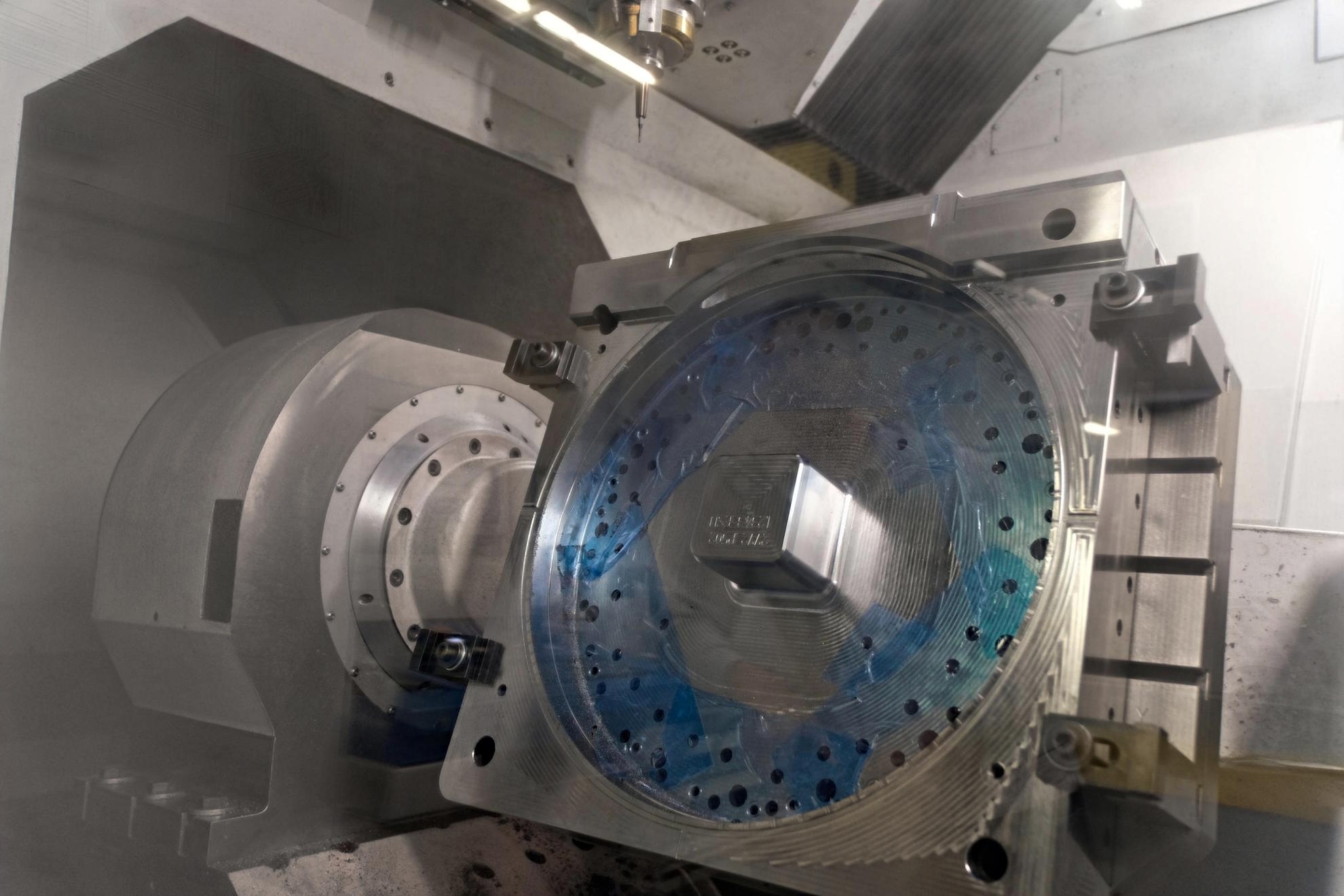

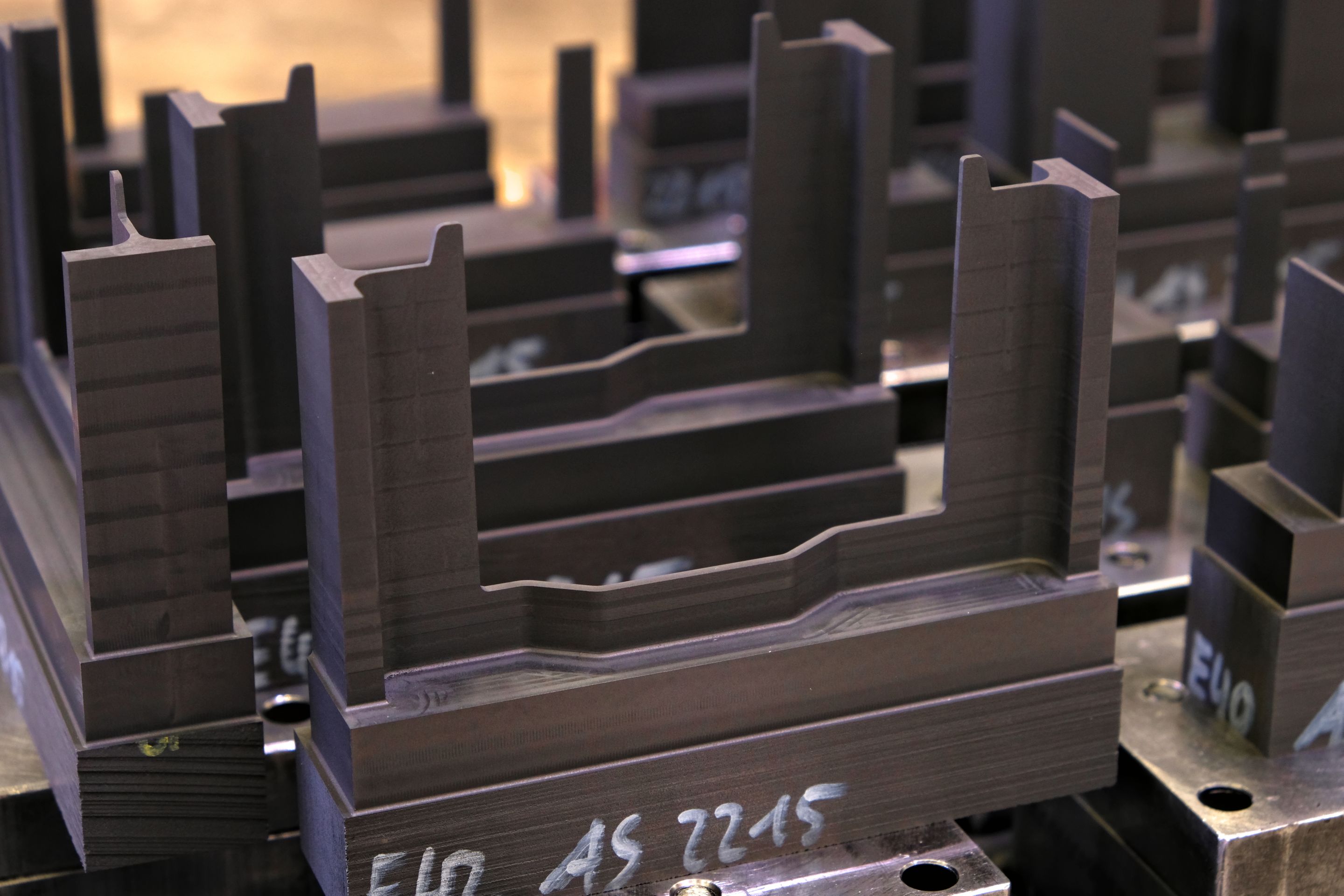

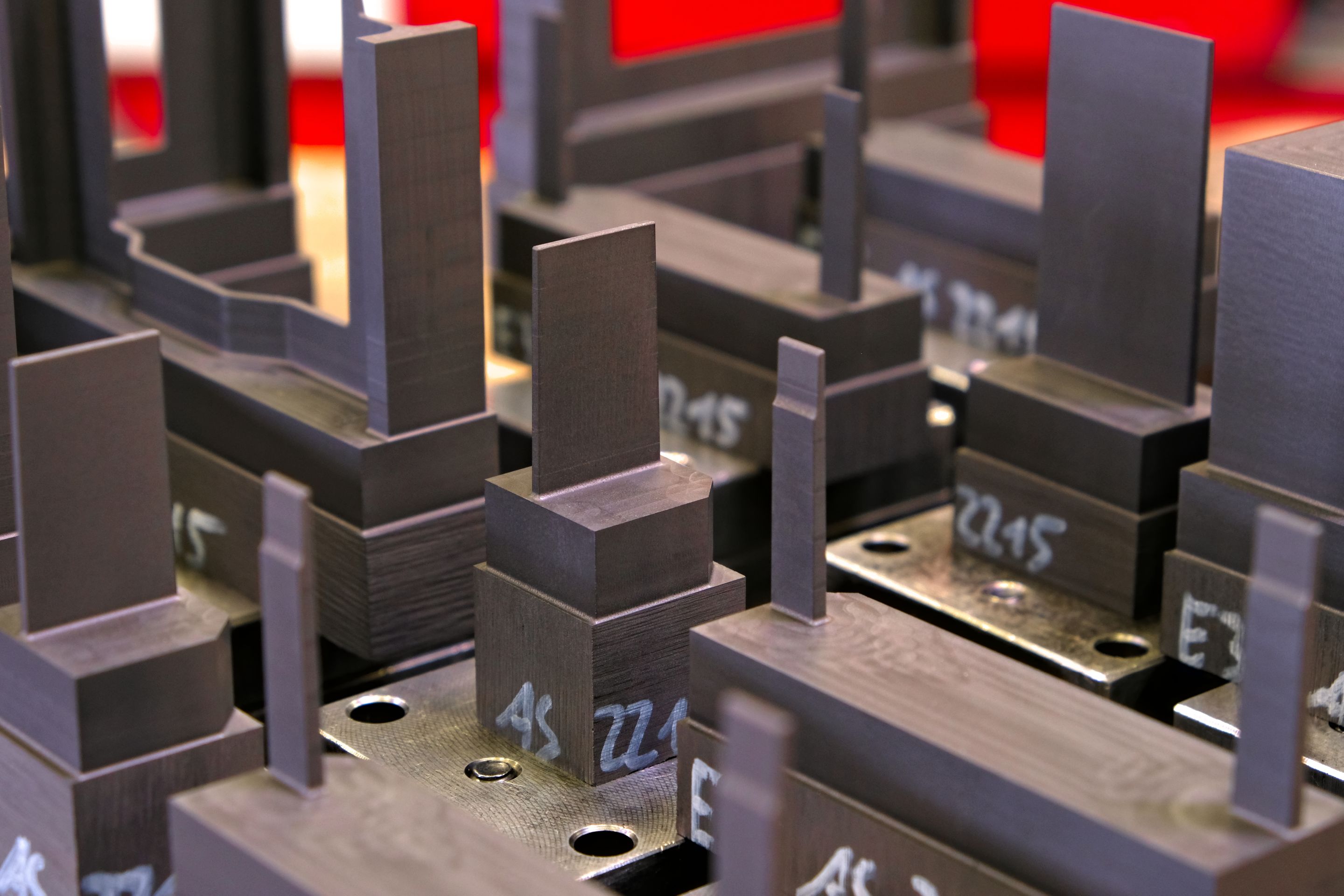

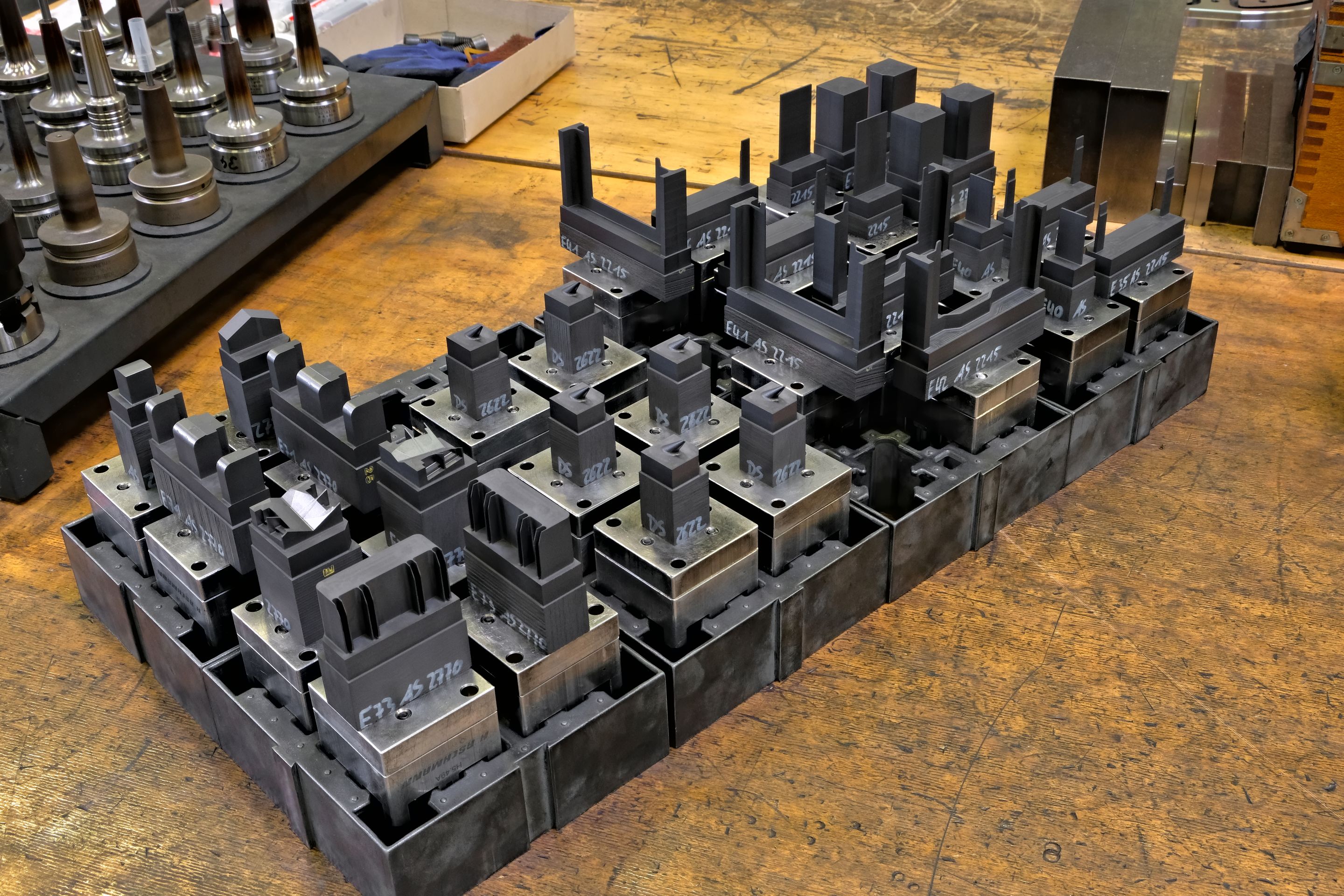

At Richter Werkzeugbau GmbH, the toolmaking department brings together many years of experience from a motivated team with state-of-the-art manufacturing technology. A versatile and highly redundant machine base enables the precise production of a wide range of components.

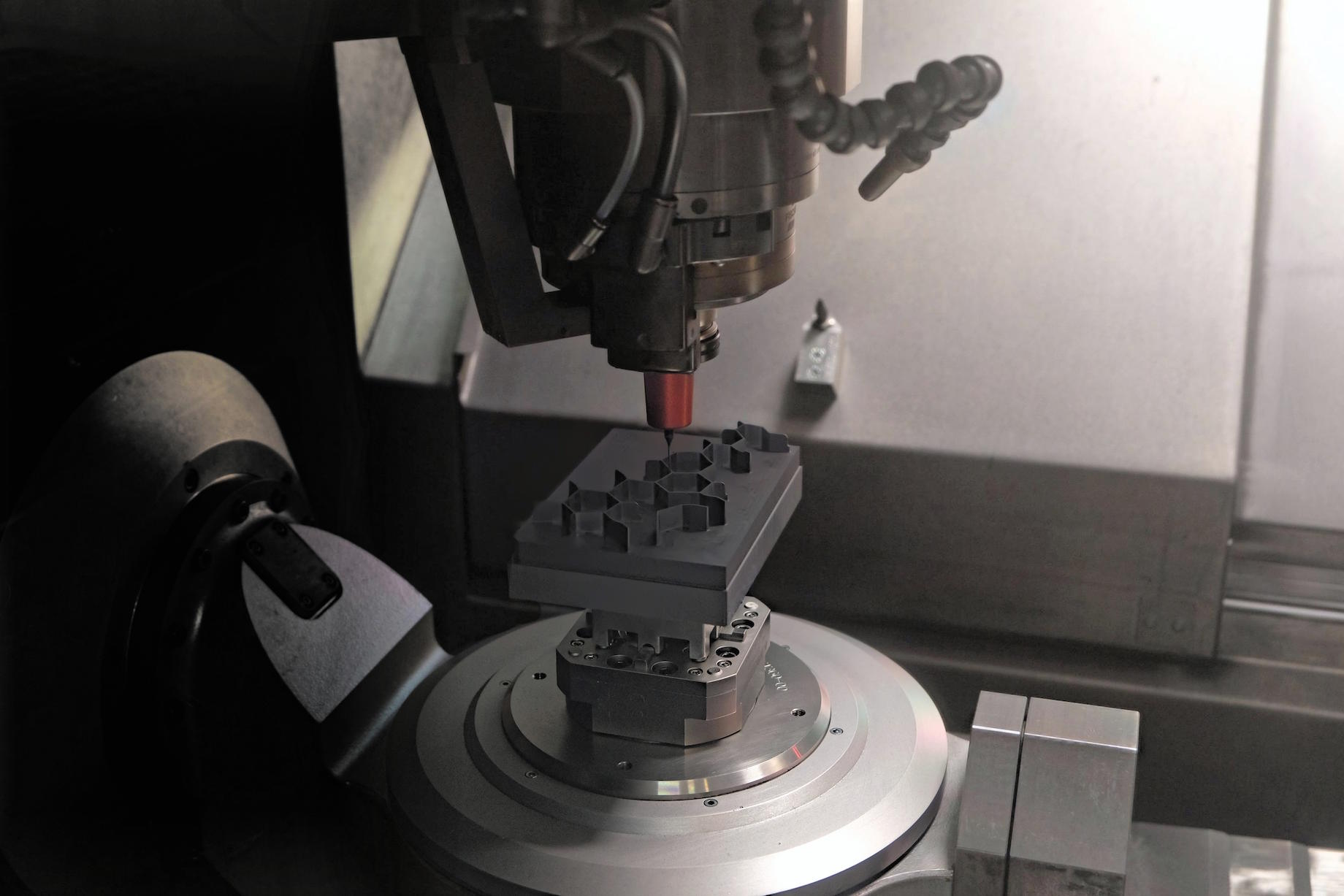

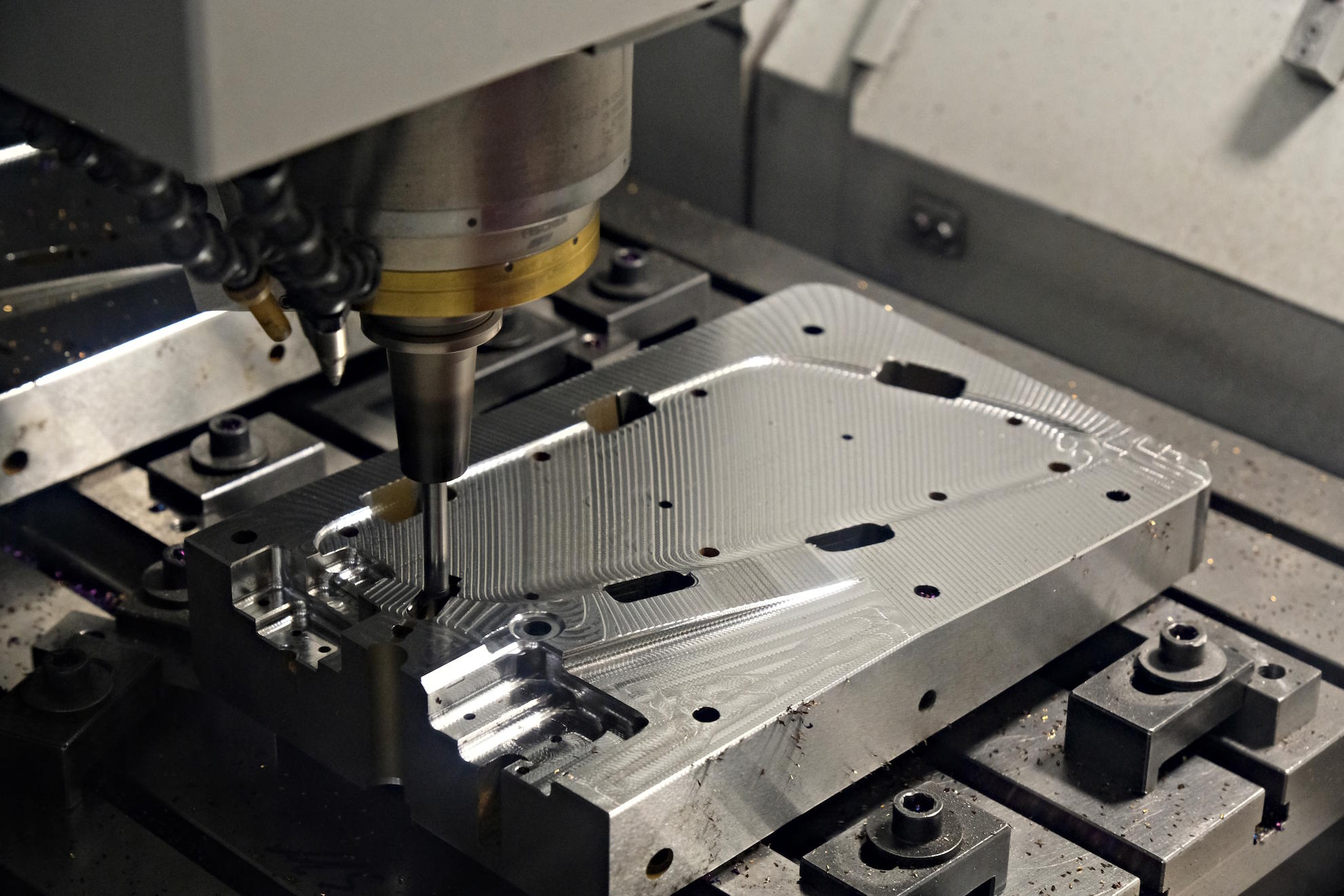

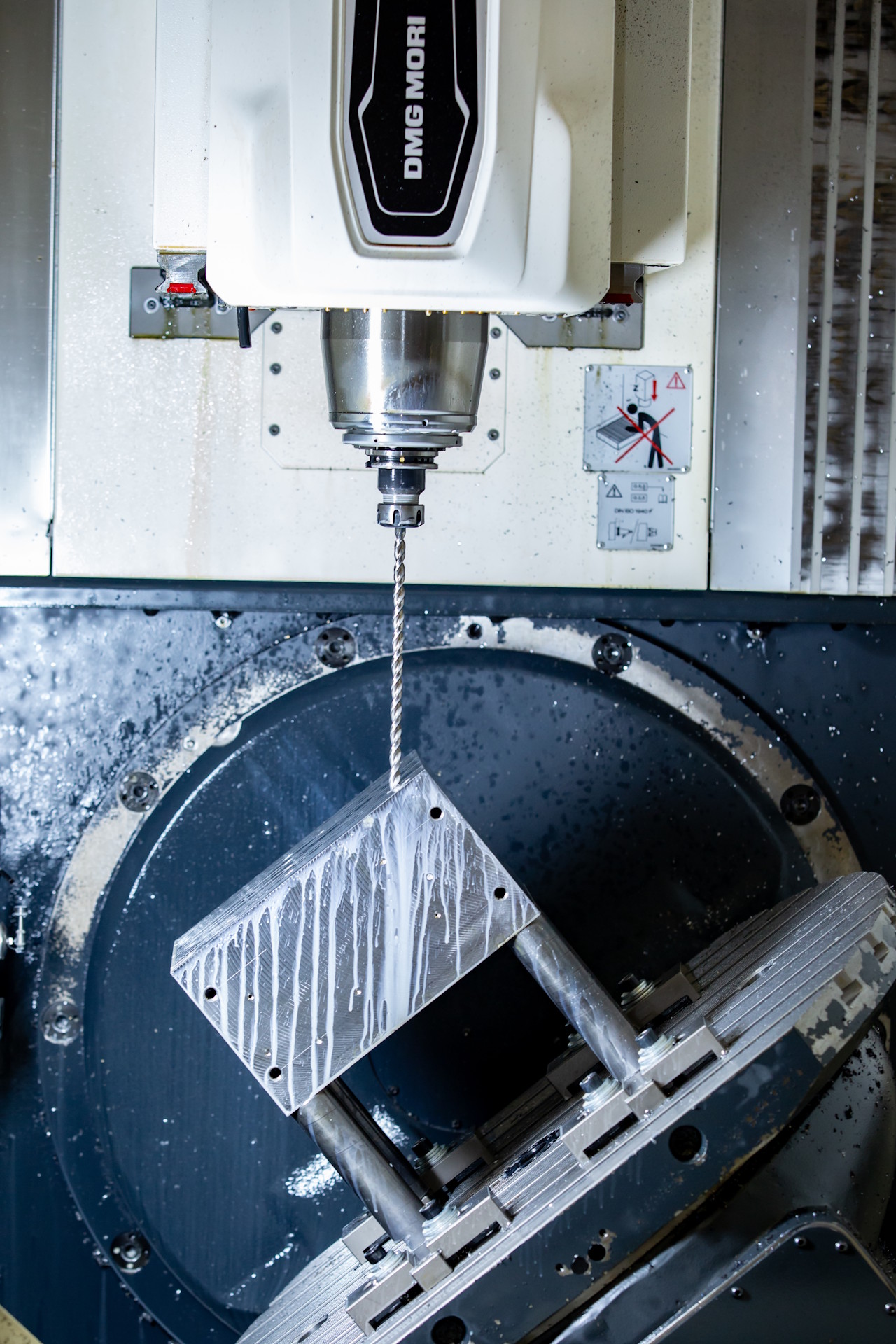

In addition to conventional CNC milling machines, we are increasingly relying on cutting-edge HSC machines with 5-axis technology and integrated automation. This combination is the key to producing complex geometries with consistently high accuracy and high productivity. In conjunction with our extensive vertical integration, we ensure the renowned quality of the components we manufacture.

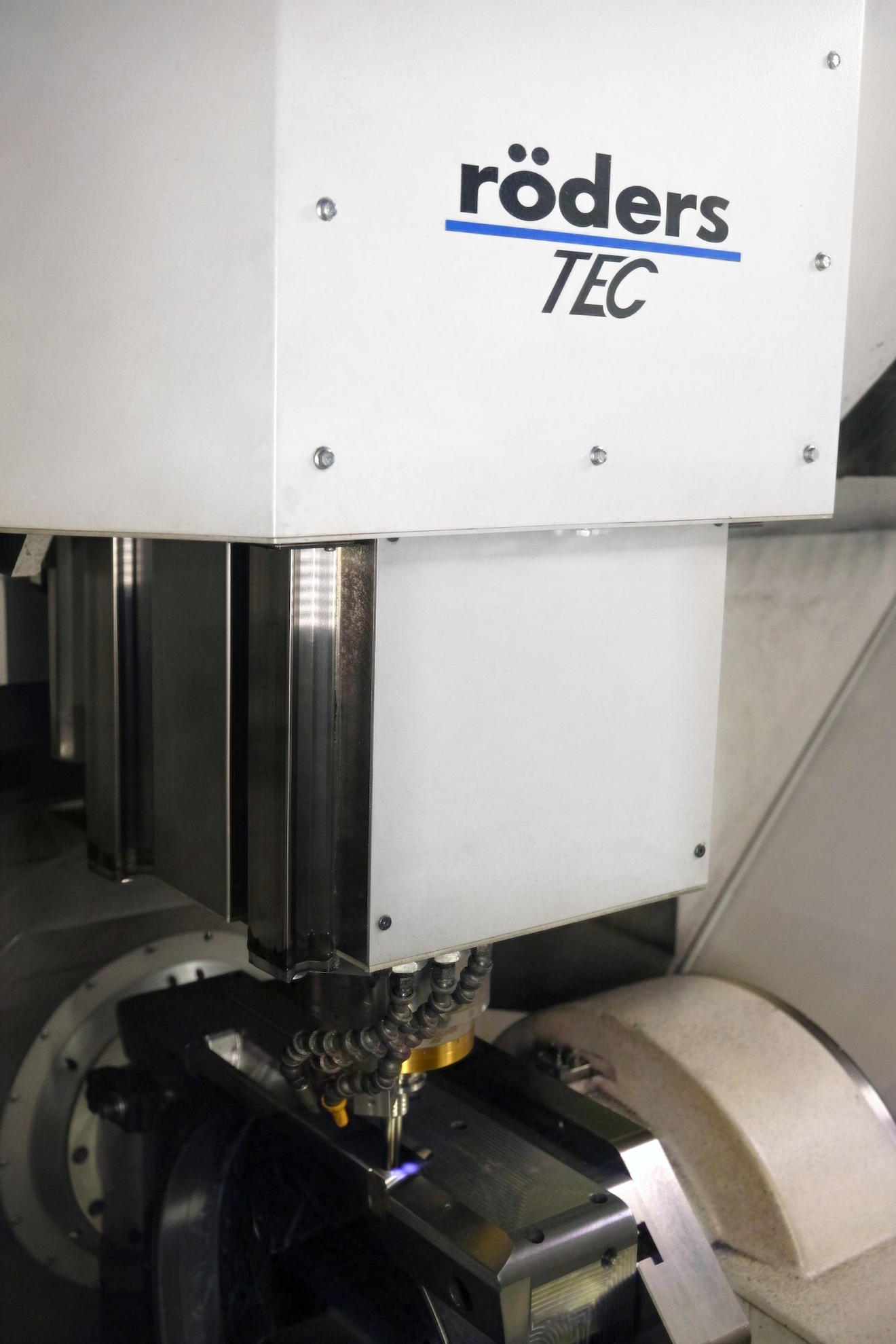

In our largely digitized single-part production, an experienced team of skilled professionals and master craftsmen – supported by customized software solutions (Cimatron) and state-of-the-art CNC machines from renowned manufacturers (DMG, Röders, OPS-Ingersoll, and Mitsubishi) – manufactures all required components according to the design specifications.

When needed, we can expand our manufacturing capabilities through cooperation with long-standing partners in new, innovative technologies such as 3D printing in steel and plastic, or vacuum brazing. This enables us to realize even unusual geometries, as required in demanding toolmaking projects or robotic handling systems.

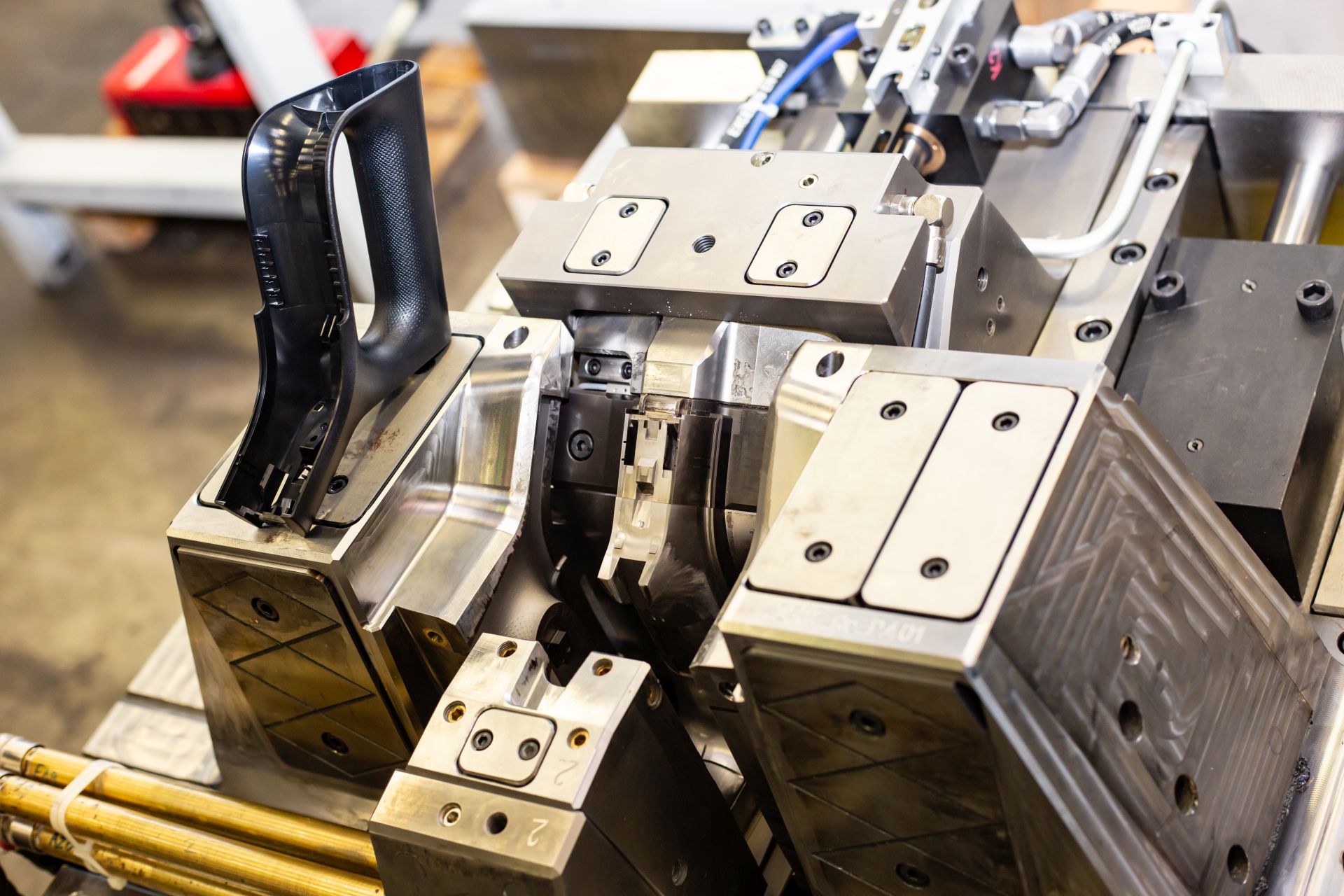

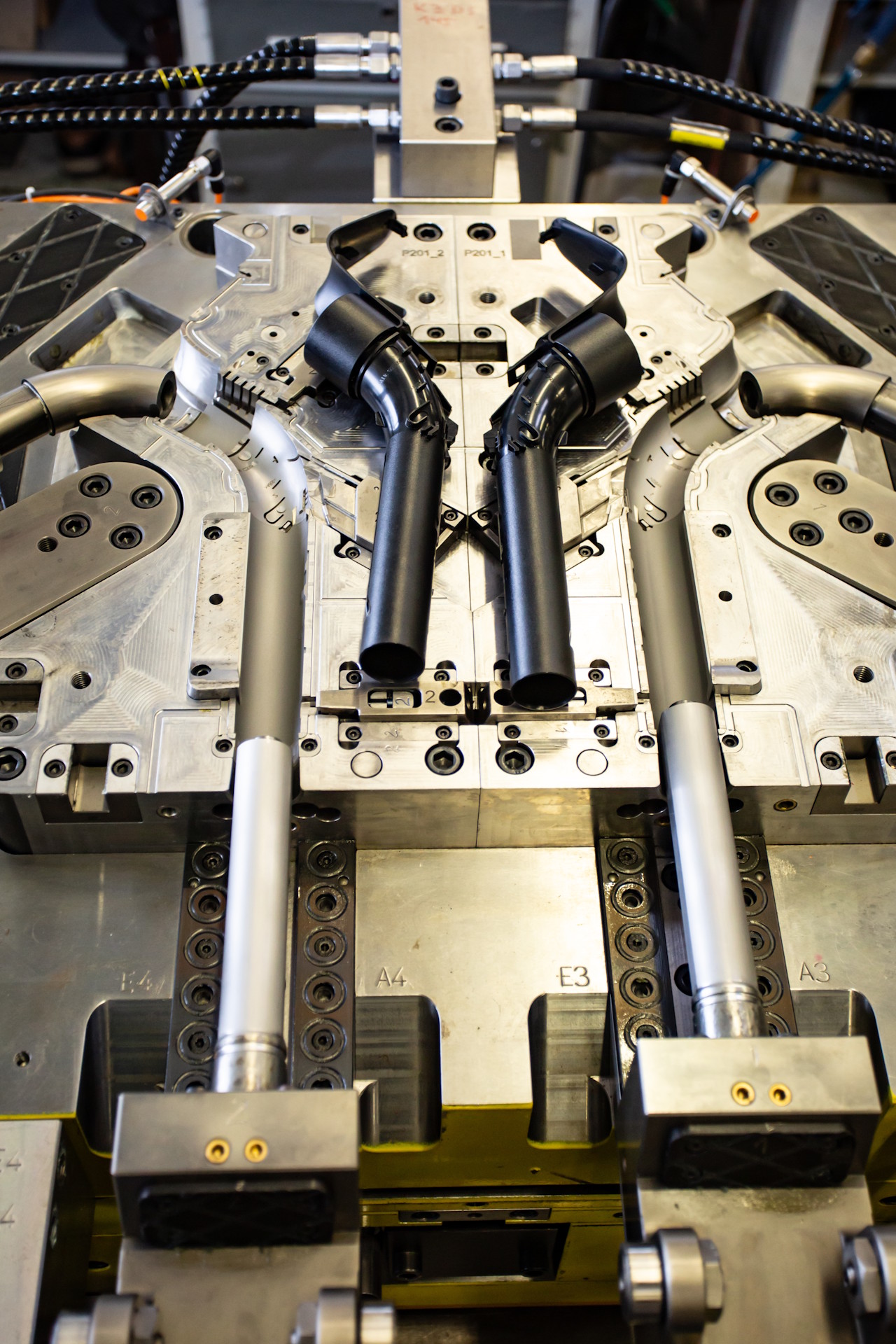

Final assembly of all components into the finished tool takes place at the workbench. A well-coordinated team of tool mechanics ensures that all individual components are precisely matched and that the mechanical function of the tool operates flawlessly – delivering accurate results that meet the highest standards, even under demanding serial production conditions. High-tech coatings and laser structuring are just as much a part of our everyday work as all other common tool surface finishes.

Our highly motivated employees ensure that even challenging requests, important changes, or urgent repairs are always carried out across departments with the same care, precision, and punctuality.